Industrial processes constantly generate dust, fumes, and microscopic pollutants that pose risks to equipment, workers, and the environment. Power plants, cement kilns, steel furnaces, chemical reactors, and biomass boilers release massive volumes of flue gas every day, and without proper filtration, these emissions contribute to air pollution and regulatory violations. One of the most reliable and widely used filtration technologies to address this challenge is the Electrostatic Precipitator (ESP).

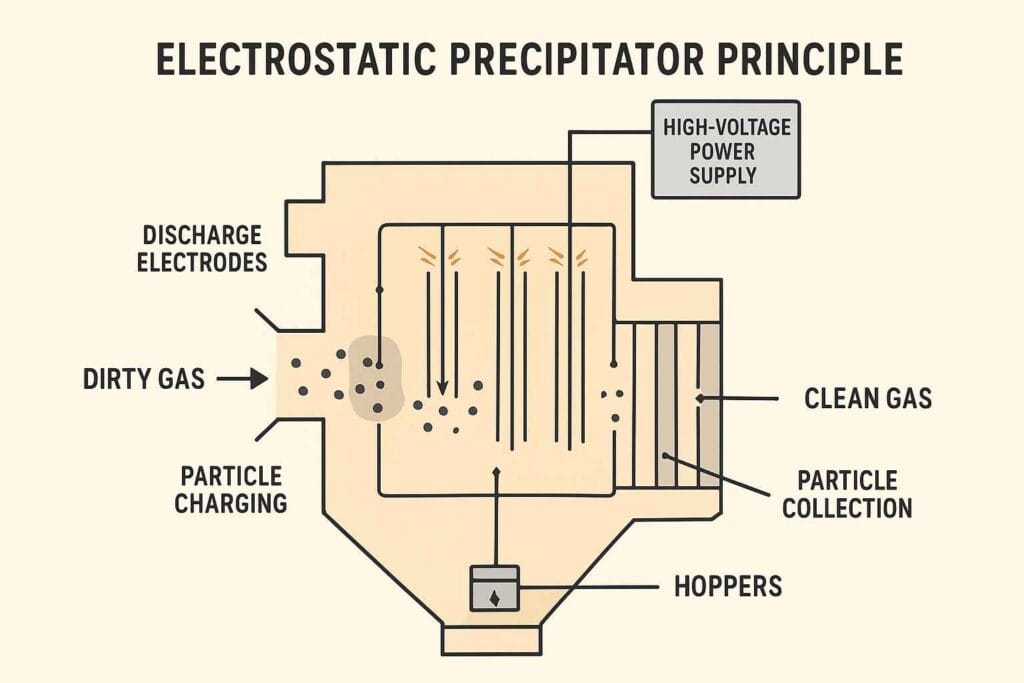

An ESP cleans industrial air by electrically charging particles and collecting them on oppositely charged plates, achieving extremely high filtration efficiency with low pressure drop. This principle allows industries to maintain compliance, protect equipment, and operate sustainably.

الیکٹروسٹیٹک پریپیٹیٹر کیا ہے؟

An electrostatic precipitator is an air filtration device that removes dust and particulate matter from industrial gas streams using high-voltage electrostatic forces. Unlike bag filters or scrubbers, ESPs do not rely on physical filtration media. Instead, they use electric fields to trap fine particles that would normally escape other systems.

An ESP consists of discharge electrodes, collecting plates, a high-voltage power supply system, a rapping mechanism for cleaning, and hoppers where the collected dust is stored. Because ESPs can operate at high temperatures and handle large gas volumes, they are commonly installed in large industrial plants where filtration requirements are demanding.

Ensure Clean Air and Regulatory Compliance Today

The Electrostatic Precipitator Principle Explained

The core working principle of an ESP is based on electrostatic charging and attraction. When dirty gas enters the chamber, electrodes create a corona and discharge a field of ionized gas produced by high-voltage direct current. As the gas molecules ionize, electrons and ions attach to dust particles, giving them a negative charge. Oppositely charged collection plates then attract and trap these particles. Once they settle on the plates, rapping hammers periodically shake the deposits into dust hoppers, ensuring uninterrupted operation.

The process relies on fundamental electrical forces. According to Coulomb’s law, charged particles experience an attractive force proportional to the electric field strength and inversely proportional to the distance between the electrodes and plates. Because this attraction is extremely strong, ESPs can collect both coarse particles and ultrafine PM2.5 and PM1 even when gas velocity is high. This is why electrostatic filtration remains one of the most efficient technologies for industrial emission control.

Step-by-Step Working Mechanism of ESP

The operation of an electrostatic precipitator can be understood as a sequence:

Dirty gas enters the ESP inlet and flows through a pre-defined path between discharge electrodes and collecting plates. The electrodes are energized with a high-voltage transformer rectifier unit, usually between 30–70 kV, generating corona discharge. Dust particles passing through this ionized zone become electrically charged. Once charged, they migrate toward the grounded collecting plates and adhere to the surface. Rapping systems periodically strike the plates to dislodge deposited dust, which falls into hoppers for disposal. The cleaned air leaves the outlet, complying with emission norms and environmental standards.

This continuous cycle allows ESPs to operate non-stop in harsh industrial environments without significant pressure loss.

ہمارے حل کی حد دریافت کریں:

Electrostatic Precipitators کی اقسام

Two of the most widely used ESP configurations are dry ESPs and wet ESPs. Dry ESPs are suitable for ash, cement dust, sinter dust, and other dry particulates. Wet ESPs are used for sticky, corrosive, and high-resistivity dust such as tars, acidic vapors, and heavy metal fumes, where water washing prevents re-entrainment of collected material.

ESPs are further classified into plate-type and tubular designs. Plate-type ESPs consist of parallel metal plates and suspended electrodes, commonly found in power and cement plants. Tubular ESPs feature cylindrical collection surfaces and are often used in chemical and petrochemical applications where gas flow is moist or corrosive. ESPs also exist in single-stage and two-stage configurations, depending on whether particle charging and collection occur simultaneously or in separate chambers.

What Determines ESP Efficiency?

The filtration efficiency of an ESP depends on a combination of electrical, mechanical, and environmental factors. Gas temperature, dust resistivity, voltage stability, particle size, and plate spacing all play a major role. Larger particles are easier to charge and collect, while ultrafine particles require stronger and more stable electric fields. The spacing between electrodes influences migration velocity, the speed at which particles move toward the plates. Higher migration velocity results in higher collection efficiency.

A commonly referenced model for ESP performance is the Deutsch-Anderson equation, which estimates theoretical collection efficiency based on plate area, migration velocity, and gas flow rate. Although real-world performance varies due to dust resistivity and load changes, well-designed ESPs routinely achieve more than 99 percent particulate removal.

Advantages of Using Electrostatic Precipitators

Industrial facilities rely on ESPs because they offer high efficiency at low operating cost. They remove microscopic particulates that mechanical filters struggle to capture, and they operate with minimal pressure drop, ensuring energy savings. The absence of fabric media eliminates frequent replacement costs and allows ESPs to handle high-temperature flue gases directly from boilers, kilns, or furnaces. Their ability to operate continuously makes them suitable for round-the-clock industrial processing.

Limitations and Challenges

Despite exceptional performance, electrostatic precipitators are not ideal for every application. The initial investment is higher compared to simpler filtration systems, but the long-term savings generally outweigh the cost. Some types of dust, especially those with very high or very low resistivity, cause issues such as back corona or re-entrainment. To overcome this, plants use flue gas conditioning, temperature control, humidification, or hybrid ESP configurations that blend mechanical and electrostatic filtration.

Industrial Applications of ESPs

Electrostatic precipitators are installed across a wide range of industries where particulate control is mandatory. Cement plants use ESPs for kiln and clinker cooler dust. Power stations rely on them for fly ash control after coal, biomass, or waste combustion. Steel and metallurgical industries deploy ESPs on sinter machines, blast furnaces, electric arc furnaces, and BOF converters. Chemical plants, fertilizer units, paper mills, and waste incinerators use ESPs to remove fine aerosols and corrosive fumes, maintaining safe emission standards and protecting process equipment.

ESPs vs Bag Filters

- ESPs provide extremely high efficiency with lower pressure drop, while bag filters rely on fabric media and need frequent replacement

- ESPs are ideal for hot, high-volume gas streams; bag filters are better for variable dust loads and mixed particulate compositions

- ESPs handle submicron particles efficiently, making them preferred for power and cement applications

Latest Developments in Electrostatic Precipitator Technology

Modern ESPs integrate advanced control systems that stabilize voltage and reduce power consumption. Pulse energization improves charging efficiency for fine or high-resistivity particles. Hybrid systems combine bag filters with ESP charging zones, delivering superior dust collection with lower emissions. Retrofitting and upgradation of old ESPs using modern rectifier units, automatic rapping control, and plate re-alignment significantly enhance performance without replacing the entire system.

نتیجہ

The principle of electrostatic precipitation remains one of the most scientifically efficient methods of dust removal. By charging particles and capturing them using electric forces rather than physical barriers, ESPs handle massive gas volumes at low energy cost. Their reliability, efficiency, and adaptability make them indispensable in industries that prioritize environmental compliance. As emission regulations tighten and sustainability becomes essential, electrostatic precipitators continue to evolve, ensuring cleaner air inside factories and cleaner skies outside them.

اکثر پوچھے گئے سوالات

Electrostatic precipitators work by charging dust particles with a high-voltage electric field and attracting them to oppositely charged collecting plates. When flue gas enters the ESP, discharge electrodes create a corona discharge that ionizes the air. Particles passing through this zone become electrically charged and migrate toward grounded plates where they accumulate. A rapping system periodically knocks the collected dust into hoppers, and the cleaned gas exits through the outlet. This entire process allows ESPs to remove extremely fine particulate matter with high efficiency and low pressure drop.

An electrostatic precipitator removes dust, smoke, and particulate pollutants from industrial gas streams using electrostatic forces instead of fabric filters. It is installed in industries such as power plants, cement factories, steel units, chemical plants, and waste incinerators to ensure emission levels remain within environmental standards. Its purpose is to deliver cleaner air, protect equipment, improve workplace safety, and reduce atmospheric pollution.

An ESP works by applying high-voltage DC power to discharge electrodes, creating a strong electric field that ionizes gas molecules. Dust particles pick up these charges and are pulled toward grounded collecting plates due to electrostatic attraction. Over time, collected dust forms a layer, which is removed by a mechanical rapping system and discharged into hoppers. Even at high temperatures and large gas volumes, ESPs maintain excellent filtration efficiency.

An electrostatic precipitator works on the principle of particle charging and electric field attraction. As dirty gas passes between charged electrodes and grounded plates, the particles become ionized and electrically charged. These charged particles are forced onto collection surfaces where they adhere. Vibrators or rapping hammers periodically remove this dust layer so that the plates stay clean and the ESP continues working continuously without shutdown.

An electrostatic precipitator is an air pollution control device used to remove harmful particulate matter from industrial exhaust gases. It uses high-voltage electric fields instead of fabric filters or water sprays. Because ESPs can handle hot, corrosive, and dusty gases while removing even sub-micron particles, they are widely used in heavy industries for emission control and environmental compliance.