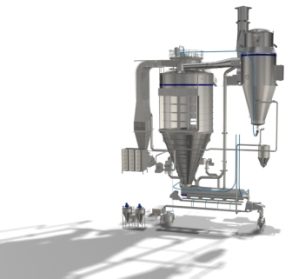

ProJet CIP Cleaning in Place Filter

Special Feature of the round Filter ProJet CIP

- Optimized geometry with a significantly reduced exhaust velocity between the filter bags that can be offered by a length of up to 8 m

- Reducing the number of mounting parts due to a longer filter bags, which leads to a reduction of the compressed air and CIP washing liquid?

- New development of clean gas chamber from a hygienic point

- Reduction of installation parts in the clean gas range and thus additional reduction in maintenance time

- No special tools for assembly / disassemble, maintenance and service necessary

- Equipped with ProTex CIP filter media that has been optimized for perfect wash-ability, short drying times and excellent clean-ability.

Rengöringssystem för Process Filter ProJet Mega

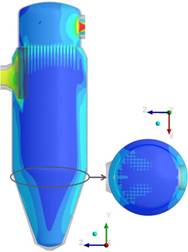

Avgörande betydelse för en energieffektiv drift av ett påsfiltersystem har injektorsystemet med vilket jetpulsen genereras för regenerering av filtermediet. Intensiv-Filter har utvecklat Coanda-injektorn och patenterat. Coanda-injektorn drar fördel av den så kallade Coanda-effekten där strålen följer en krökt yta. Detta resulterar i att en maximal rengöringsintensitet uppnås och samtidigt effektiv separation av filterkakan från filtermediet.

The cleaning control of the new process filter ProJet mega via microprocessor technology and fieldbus systems. Intensiv-Filter sets for a long time tested and patented JetBus controller that regulates the cleaning pressure. The timing of the pressure pulses is varied depending on the requirement. Optionally, a fixed timing, or a differential pressure control can be applied with variable cycle times.

Product Recovery with the ProJet CIP