Pisarne

SEDEŽ

Nemčija

-

Intenzivni filter Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Nemčija/Nemčija - +49 20534200990

OBMOČNI URAD

Velika Britanija

-

Intenzivni filter Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Velika Britanija - +44 1922 628893

OBMOČNI URAD

Združeni arabski emirati

-

Intenzivni filter Himenviro Technologies FZE – LLC

Poslovni center, Sharjah Publishing City Free Zone, Sharjah, ZAE - +971-556074697

OBMOČNI URAD

Indija

-

Intensiv-Filter Himenviro Private Limited

D-247/11, sektor-63, Noida - 201301, Uttar Pradesh, Indija - +91-120-4642-500

OBMOČNI URAD

Indija

-

Intensiv-Filter Himenviro Private Limited

D-247/11, sektor-63, Noida - 201301, Uttar Pradesh, Indija - +91-120-4642-500

OBMOČNI URAD

Indija

-

Intensiv-Filter Himenviro Private Limited

D-247/11, sektor-63, Noida - 201301, Uttar Pradesh, Indija - +91-120-4642-500

Glass Industry Air and Dust Filtration Solutions

The glass manufacturing industry is characterized by high temperatures, the use of raw materials that generate fine dust, and the production of volatile fumes. These factors pose significant risks to worker health, environmental compliance, and product quality. Our air and dust filtration systems are engineered specifically for the glass industry, ensuring efficient capture of airborne particulate matter, fumes, and gases at critical stages of production. Our solutions help manufacturers meet regulatory standards, protect workers, and ensure that products maintain their high quality without contamination.

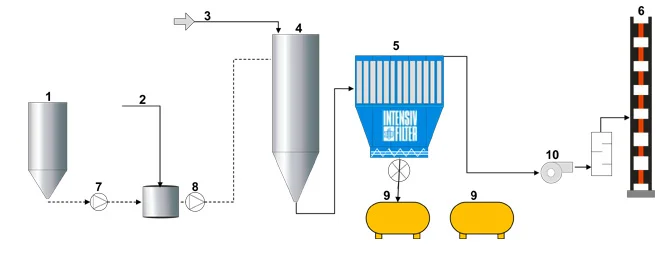

Proces

Filter za steklarno peč

- 1. Posoda za NaOH

- 2. Voda

- 3. Vroč plin iz steklenega korita

- 4. Reaktor za dušenje

- 5. Filter za steklarno peč

- 6. Dimnik

- 7. Dozirna črpalka

- 8. Črpalka za dušenje

- 9. Transportna posoda

- 10. Povzročen prepih

Zahtevane specifikacije

Applications for Glass Industry Dust Control

Filters airborne dust during the handling and storage of raw materials like silica, soda ash, and limestone, ensuring that dust doesn’t spread to other areas of the facility.

Controls airborne pollutants and particulate matter produced during the melting process, ensuring clean air around high-temperature furnace areas.

Reduces dust and fine particulate matter generated during the forming and molding of glass products, preventing contamination and enhancing product integrity.

Povežite se z nami za strokovni posvet

Raziščite naše druge storitve!

Pogosto zastavljena vprašanja

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.