The Science Behind Clean Air in Industries

Dust generation is inevitable in industries such as cement, steel, power, pharmaceuticals, food processing, and chemicals. Every stage of production—from raw material handling and crushing to grinding, combustion, or packaging—releases fine particulate matter into the air. These particles vary in size, ranging from visible coarse dust to invisible sub-micron particles that can remain airborne for long periods. If left uncontrolled, airborne dust not only affects worker health, leading to respiratory illnesses and occupational hazards, but also damages machinery through abrasion, reduces product quality through contamination, and results in costly downtime. Moreover, excessive emissions can lead to non-compliance with environmental regulations, inviting penalties and operational restrictions.

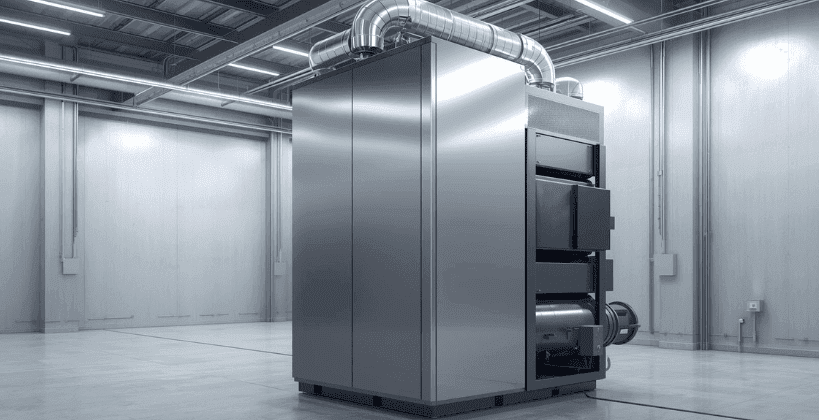

Dust collector machines provide the engineered solution to this challenge by capturing, filtering, and safely disposing of dust at its source. These systems are not merely accessories but critical components of industrial infrastructure, ensuring that plants can operate efficiently, safely, and in line with international emission norms.

At Intensiv-Filter Himenviro, we specialize in designing and supplying high-performance dust collectors that combine advanced filtration technologies—such as baghouse filters, electrostatic precipitators, and cyclones—with robust engineering tailored to industry-specific requirements. Our solutions are built for long-term reliability, even in demanding environments characterized by high dust loads, extreme temperatures, and aggressive gas compositions.

To fully appreciate their role in industrial sustainability, it is essential to understand the technical working principle that allows dust collector machines to transform polluted process gases into clean, breathable air.

Core Working Principle of Dust Collectors

A dust collector operates on the principle of air-to-cloth filtration or particle separation, depending on the design and application. The fundamental goal is simple yet critical: allow clean air to pass through the system while capturing and retaining dust particles within a controlled collection chamber. This ensures that emissions remain within regulatory limits while keeping industrial environments safe and efficient.

The process follows a structured sequence of steps:

1. Inlet and Dust-Laden Air Distribution

Dust-laden air first enters the dust collector through an inlet ducting system. The geometry of the inlet is crucial—poor design can cause turbulence, uneven distribution, or filter overloading, reducing efficiency. To address this, modern systems use flow distributors, baffles, or diffusers to evenly spread the dust-laden air across the filtration chamber. Advanced facilities also rely on Computational Fluid Dynamics (CFD) simulations to optimize airflow patterns, reduce pressure loss, and enhance separation efficiency.

2. Particle Separation Mechanisms

Depending on the type of dust collector, different engineering principles are applied to separate particles from the air stream:

- Inertial Separation (Cyclone Collectors):

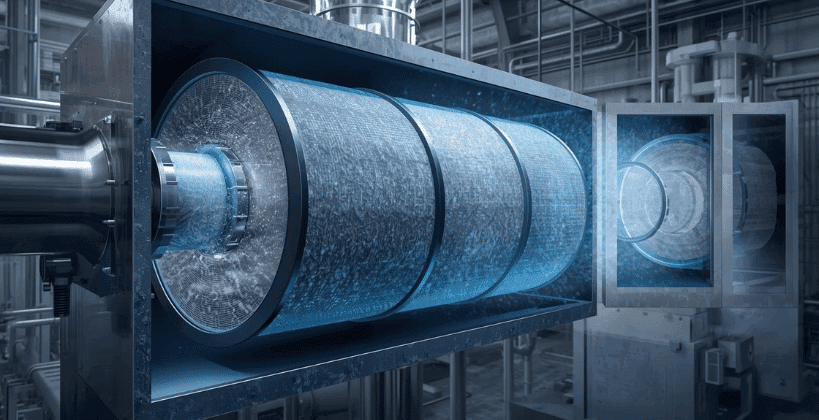

The gas stream is directed into a spiral or vortex motion. Centrifugal force pushes heavier particles outward toward the cyclone wall, where they lose velocity and fall into the hopper. Cyclones are robust, low-maintenance, and effective for coarse dust particles above 10 microns. - Surface Filtration (Baghouse / Fabric Filters):

Air is drawn through fabric filter bags or pleated cartridge filters, where dust is trapped on the surface of the filter media. Over time, a thin layer of particles—known as the dust cake—forms, which actually increases filtration efficiency by capturing finer particles.

Filter media selection is critical and depends on process conditions:

-Polyester or Polypropylene: General-purpose applications.

-Aramid (Nomex): High-temperature resistance.

-PTFE (Teflon-coated): Chemical resistance and moisture repellence.

- Electrostatic Precipitation (ESPs):

Dust particles are electrically charged by high-voltage corona electrodes and then attracted to oppositely charged collection plates. The collected dust is periodically dislodged by rapping systems. ESPs are especially effective for fine, sub-micron particles and can achieve collection efficiencies greater than 99.9%, making them suitable for power plants and steel mills. - Absorption/Impaction (Wet Scrubbers):

Dust particles are captured by liquid droplets, usually water or chemical solutions. The liquid then carries the dust to a settling or separation chamber. Wet scrubbers are ideal for sticky, hygroscopic, or explosive dusts and also help in simultaneous gas absorption, removing pollutants like SO₂ or acid mists.

3. Filtration and Pressure Differential

As dust-laden air passes through the filter media, resistance to flow creates a pressure drop across the system. Monitoring and maintaining this pressure within the optimal range—typically 1000–1500 Pa for baghouses—is essential. A stable pressure drop indicates efficient operation, while a rising pressure drop signals filter clogging. Modern dust collectors are equipped with differential pressure gauges and PLC-based monitoring systems to ensure consistent airflow and performance.

4. Cleaning Systems

Over time, dust accumulates on filter surfaces and reduces permeability. To restore airflow, dust collectors use automatic cleaning systems:

- Pulse Jet Cleaning: Short, high-pressure bursts of compressed air dislodge the dust cake from the filter surface, keeping the filter continuously clean.

- Shaking Mechanism: Mechanical vibrations shake the dust off the filters, suitable for smaller collectors or intermittent operations.

- Čiščenje z obratnim pretokom zraka: A controlled reverse flow of air gently dislodges accumulated dust, extending filter life.

These systems are engineered to minimize downtime, extend filter bag life, and reduce maintenance costs while maintaining high filtration efficiency.

5. Collection and Disposal

Once separated, the dust falls into lijaki positioned at the base of the collector. From there, it is discharged via rotary airlocks, screw conveyors, or pneumatic transport systems into storage bins or disposal units. Continuous discharge systems ensure that dust removal does not interrupt the operation, even in plants handling high dust loads around the clock.

Technical Parameters That Define Efficiency

The efficiency and reliability of a dust collector are not determined by a single factor but by a combination of interrelated technical parameters. These parameters guide the design, operation, and performance evaluation of the system:

- Air-to-Cloth Ratio (A/C Ratio):

This is the ratio of air volume handled (m³/min) to the filter surface area (m²). A lower A/C ratio means that each square meter of filter media handles less air, leading to more effective filtration and lower wear on the bags. However, it also requires a larger collector size. Selecting the correct A/C ratio is critical for balancing filtration efficiency, cost, and system footprint. - Filtration Velocity:

The speed at which air passes through the filter media directly affects performance. Excessive velocity can cause dust re-entrainment (particles escaping back into the clean air stream), while too low a velocity makes the system uneconomical. Engineers carefully calculate optimal filtration velocity based on dust type, particle size distribution, and operating conditions. - Collection Efficiency:

This is usually expressed as a percentage, ranging from 95% for simpler systems to over 99.9% for advanced baghouses and ESPs. High-efficiency collectors can capture even sub-micron particles, ensuring compliance with strict environmental regulations and protecting worker health. - Padec tlaka:

The difference in air pressure before and after the filter media indicates resistance to airflow. A stable pressure drop reflects consistent system performance, while a sudden rise may signal filter clogging. Maintaining the right balance ensures energy efficiency and avoids strain on fans and blowers. - Emission Levels:

The ultimate measure of efficiency is the concentration of dust in the cleaned air. Measured in milligrams per cubic meter (mg/Nm³), modern collectors are designed to comply with stringent emission standards, often below 30 mg/Nm³, as per CPCB (India), OSHA (USA), and EU norms. In some cases, emission levels can be reduced to <5 mg/Nm³ with advanced filter media.

Advantages of Intensiv-Filter Himenviro Dust Collection Systems

Intensiv-Filter Himenviro offers dust collectors that stand out through advanced engineering and practical design features. Our systems deliver superior performance in demanding industrial conditions:

- Tailored Design: Each solution is engineered to match specific industry requirements—whether it’s handling coarse cement dust, abrasive metallurgical dust, or fine pharmaceutical powders. Our engineers account for factors such as dust concentration, temperature, humidity, and corrosiveness.

- Visoko zmogljivi materiali: Filter bags and cartridges are made from advanced fabrics capable of withstanding high temperatures (up to 250°C) and chemically aggressive gases. Options include aramid, PTFE, and fiberglass composites, ensuring durability and long service life.

- Automated Controls: Modern systems come with PLC-based monitoring that tracks differential pressure, initiates cleaning cycles automatically, and monitors hopper levels. This reduces manual intervention and ensures round-the-clock reliability.

- Energijska učinkovitost: By optimizing fan design, minimizing pressure drop, and incorporating advanced cleaning mechanisms, our dust collectors consume less energy, lowering operational costs without compromising performance.

- Safety Integration: For industries dealing with explosive or combustible dust, our systems include explosion relief vents, spark detection and arrestors, and integrated fire suppression systems, ensuring compliance with ATEX and NFPA standards.

Real-World Applications

Dust collector machines from Intensiv-Filter Himenviro are versatile, serving industries with unique challenges:

- Cementna industrija: Efficiently manages kiln exhaust gases and clinker cooler dust, where dust loads are extremely high and temperatures can exceed 200°C.

- Elektrarne: Captures fly ash from coal-fired boilers, ensuring compliance with emission norms and preventing environmental pollution.

- Metallurgical Processes: Filters dust and fumes from blast furnaces, converters, and sinter plants, where particulates are abrasive and contain heavy metals.

- Farmacevtski izdelki: Provides safe handling of fine powders, ensuring cleanroom standards are maintained while protecting workers from exposure.

- Predelava hrane: Controls flour, sugar, and grain dusts, which are not only respiratory hazards but also highly combustible, thereby reducing the risk of dust explosions.

Conclusion: Engineering Clean Air for Industrial Growth

The working principle of a dust collector machine lies in precision engineering—managing airflow, filtration, and separation to achieve near-zero emissions. For industries worldwide, this technology ensures compliance, improves efficiency, and safeguards workers and communities.

pri Intenzivni filter Himenviro, we combine German engineering heritage with cutting-edge design innovations to deliver dust collection solutions that perform reliably under the most demanding conditions. Whether it’s fine pharmaceutical dust or heavy cement particulates, our systems are designed to ensure clean air, safe workplaces, and sustainable operations.

Odkrijte naš nabor rešitev:

Pogosto zastavljena vprašanja

A dust collector works by drawing in dust-laden air, separating particles through filtration or other mechanisms (like cyclonic separation or electrostatic precipitation), and discharging clean air back into the environment. The captured dust is collected in hoppers or bins for safe disposal.

Dust collectors are critical for ensuring worker safety, preventing equipment damage, maintaining product quality, and complying with environmental emission regulations. Without them, industries face risks of respiratory illnesses, machinery wear, contamination, and penalties for non-compliance.

- Cyclone Collectors – for coarse dust using centrifugal force.

- Vrečasti filtri – for fine particles using fabric filtration.

- Electrostatic Precipitators (ESPs) – for sub-micron dust using electrical charging.

- Wet Scrubbers – for sticky, hygroscopic, or explosive dust, using liquid absorption.

Efficiency is determined by parameters like:

- Air-to-cloth ratio

- Filtration velocity

- Collection efficiency (%)

- Pressure drop (Pa)

- Emission levels (mg/Nm³)

Modern dust collectors can achieve over 99.9% efficiency with emissions as low as <5 mg/Nm³.