Kantoren

HOOFDKANTOOR

Duitsland

- Intensiv Filter Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Duitsland/Duitsland - +49 20534200990

REGIONAAL KANTOOR

Groot-Brittannië

- Intensief filter Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Groot-Brittannië - +44 1922 628893

REGIONAAL KANTOOR

Verenigde Arabische Emiraten

- Intensieve filter Himenviro Technologies FZE – LLC

Businesscentrum, Sharjah Publishing City Free Zone, Sharjah, VAE - +971-556074697

REGIONAAL KANTOOR

Indië

- Intensief-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REGIONAAL KANTOOR

Indië

- Intensief-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REGIONAAL KANTOOR

Indië

- Intensief-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

Oplossingen voor afvalverwijdering, lucht- en stoffiltratie

De afvalverwerkingsindustrie omvat complexe processen zoals afvalinzameling, -transport, -behandeling, -verbranding en -recycling – die allemaal aanzienlijke hoeveelheden stof, schadelijke deeltjes en gevaarlijke emissies genereren. Deze emissies vormen, indien niet goed beheerd, risico's voor de gezondheid van werknemers, naleving van regelgeving en milieuveiligheid. Onze geavanceerde lucht- en stoffiltratieoplossingen zijn ontworpen om de uitdagingen van afvalbeheer aan te gaan en fijnstof en verontreinigende stoffen in elke kritieke fase af te vangen. Met op maat gemaakte systemen helpen we afvalverwerkingsbedrijven schonere werkomgevingen te behouden, schadelijke emissies te verminderen en te voldoen aan strenge normen. milieunormen.

Stoffiltratieproces in de afvalverwerkingsindustrie

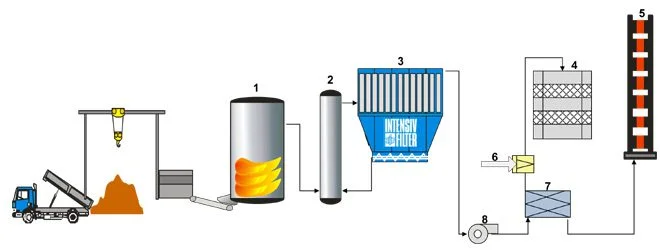

Filter voor reactor

- 1. Verbrandingsinstallatie

- 2. Reactor

- 3. Filter voor reactor

- 4. Denox-installatie

- 5.Schoorsteen

- 6. Aardgas

- 7. Warmtewisselaar

- 8. Beademingsapparaat

Vereiste specificaties

Afvalverwerkingsproces van afvalverbranding

Typische ontwerpgegevens | Afvalverbranding |

|---|---|

Gasvolume | 60,000-100,000 |

Gastemperatuur | 140 – 180 |

Soort stof | Vliegas |

Reststofgehalte | < 10 |

Ruw gasstofgehalte | 5 – 10 |

Schoonmaak | online |

Filtermedium | |

Explosieveilig ontwerp | niet nodig |

Sorptiemiddel | Calciumhydroxide, ovencokes, actieve kool, natriumbicarbonaat |

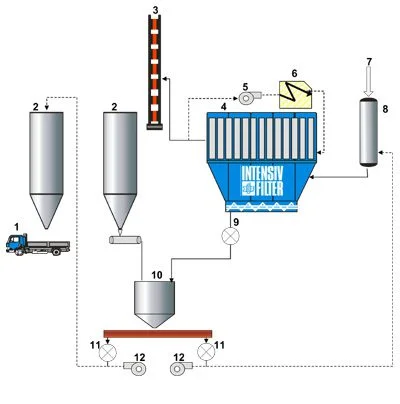

Afvalverwerkingsproces van rioolslibverbranding

- 1. Eindstation

- 2. Silo

- 3. Schoorsteen

- 4. Filter voor reactor

- 5. Recirculatieluchtventilator

- 6. Verwarmingsbatterij

- 7. Afvalgas van verbrandingsinstallaties

- 8. Beademingsapparaat

- 9. Ontvangertank

- 10. Ontvangertank

- 11. Doorblaasventiel

- 12. Luchtdroger

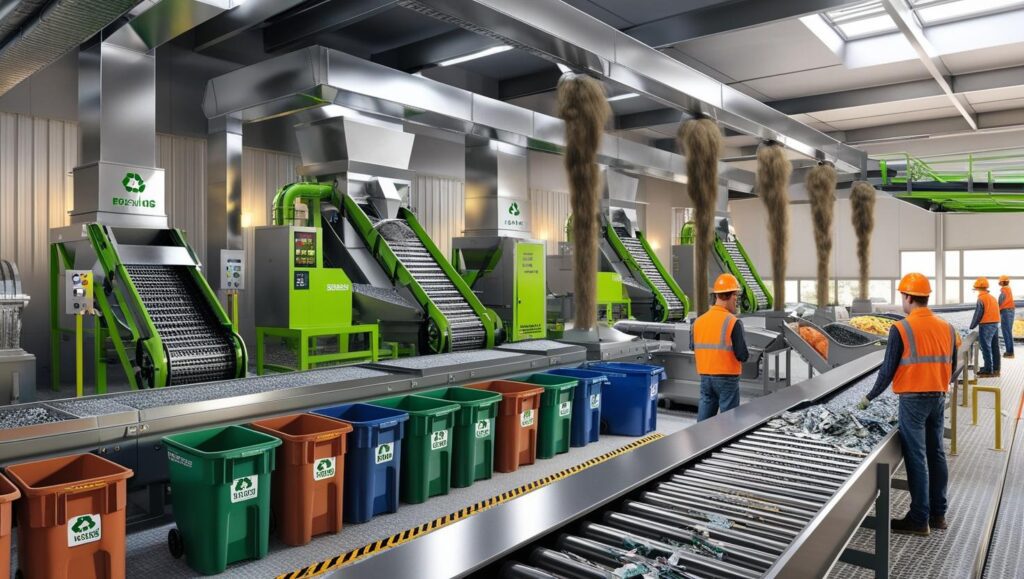

Toepassingen voor stofbeheersing bij afvalverwerking

Beheerst stof dat ontstaat tijdens afvalinzameling en -sorteringswerkzaamheden en minimaliseert zwevende deeltjes die verontreinigende stoffen kunnen bevatten.

Vangt stof- en geuremissies op bij overslagpunten tijdens het verplaatsen van grofvuil, waardoor de luchtkwaliteit in overslagstations verbetert.

Vermindert de uitstoot van hogetemperatuurverbrandingsovens, waardoor fijnstof, gevaarlijke gassen en schadelijke bijproducten worden verminderd.

Filtert stof dat ontstaat bij het sorteren, versnipperen en recyclen van materialen zoals metalen, kunststoffen en glas.

Regelgevingslandschap voor stofbeheersing |

|---|

Naleving van luchtkwaliteitsnormen |

Naleving van de gezondheids- en veiligheidsvoorschriften voor werknemers |

Beheer van gevaarlijke emissies |

Verbrandings- en explosiepreventie |

Geurbestrijdingsvoorschriften |

Duurzame milieupraktijken |

Emissiemonitoring en rapportage |

Afvalbeheerregelgeving |

Richtlijnen voor energie-efficiëntie |

Uitdagingen op het gebied van stofbeheersing |

|---|

Hoog stofvolume |

Gezondheidsrisico's |

Geuremissies |

Naleving van regelgeving |

Brand- en explosiegevaren |

Slijtage van apparatuur |

Afhandeling van gevaarlijk afval |

Milieu-impact |

Kruisbesmetting |

Belangrijke overwegingen voor effectieve stofbeheersing |

|---|

Geavanceerde stofafzuigsystemen |

Geur- en VOC-controle |

Temperatuurbestendige filtratie |

Bioaerosolfiltratie |

Realtime emissiemonitoring |

Gevaarlijke stofbeheersing |

Regelmatig onderhoud en inspectie |

Energiezuinige oplossingen |

Aangepaste plantaanpassingen |

Neem contact met ons op voor deskundig advies

Ontdek onze andere diensten!

Veelgestelde vragen

Lucht- en stoffiltratie is essentieel in afvalverwerkingsomgevingen om schadelijke deeltjes, gassen en geuren op te vangen die vrijkomen tijdens de verwerking, verbranding of het transport van afval. Deze verontreinigende stoffen kunnen ernstige gezondheids- en milieurisico's vormen als ze niet worden behandeld. Effectieve filtratiesystemen zorgen voor naleving van de regelgeving, beschermen de veiligheid van werknemers en dragen bij aan schonere processen.

Afhankelijk van het type afval en het verwerkingsproces worden verschillende filtratiesystemen gebruikt. Veelgebruikte oplossingen zijn onder andere filterzakken voor het afvangen van fijnstof, natte wassers voor het verwijderen van zure gassen en oplosbare verbindingen, en actievekoolsystemen voor geurbestrijding. Cycloonscheiders worden vaak gebruikt om grotere deeltjes af te vangen voordat fijnfiltratie plaatsvindt. Lucht-lucht warmtewisselaars kunnen ook worden gebruikt voor energieterugwinning in afvalverbrandingsinstallaties.

Filtersystemen helpen de uitstoot van stof, giftige gassen en vluchtige stoffen te verminderen, waardoor faciliteiten kunnen voldoen aan lokale en internationale milieunormen. Ze spelen een essentiële rol bij het beperken van de emissies tot onder de toegestane limieten en zijn noodzakelijk voor het verkrijgen van milieuvergunningen en het behouden van het publieke vertrouwen.