Understanding Bag Filters

Bag filters are devices used to remove dust and other particles from air or liquid. They have a simple design. They consist of a fabric bag that traps particles as air or liquid flows through it. The fabric captures the dust while allowing clean air or liquid to pass. Bag filters work by creating a barrier that blocks unwanted particles. They are effective in many settings, helping to keep environments clean and safe.

- Bag filters are commonly used in manufacturing plants to keep air clean.

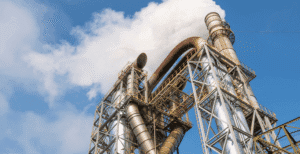

- They are found in power plants to filter dust from emissions.

- Bag filters help in food processing to ensure clean ingredients.

- They are used in water treatment facilities to remove impurities.

- Bag filters are also found in HVAC systems to improve indoor air quality.

Leading Bag Filter Manufacturers in India

- Parker Hannifin: Parker Hannifin is a well-known name in India. They make high-quality bag filters. Their products are used in many industries, such as food and beverage, chemicals, and pharmaceuticals. They have years of experience in providing filtration solutions.

- Donaldson: Donaldson is another leading manufacturer in India. They offer a wide range of bag filters for air and liquid applications. Their filters are popular for their durability and efficiency. Donaldson has a strong presence in the automotive and industrial sectors.

- Aqua Filtration: Aqua Filtration specializes in water treatment. They manufacture bag filters that help remove impurities from water. Their products are used in municipal and industrial water systems. Aqua Filtration has over ten years of experience in the filtration industry.

- Filter Concept: Filter Concept provides a variety of bag filters for different applications. Their products include filters for air, oil, and water. They focus on quality and customer satisfaction. Filter Concept has been in the industry for more than twenty years.

- Cameron: Cameron is known for its innovative filtration solutions. They design and manufacture bag filters for oil and gas, power, and water industries. Their products help improve process efficiency. Cameron has extensive experience in providing filtration technology.

- Sudarshan Filters: Sudarshan Filters is a trusted name in bag filter manufacturing. They offer custom solutions for various industries. Their filters are used in sectors like textiles and chemicals. Sudarshan Filters has been operational for over fifteen years.

Factors to Consider When Choosing a Bag Filter Supplier

When choosing a bag filter supplier, it is important to look at several key factors. These factors help ensure that the selected supplier meets the needs of the business.

- Product Quality: The supplier should offer high-quality bag filters. This means the filters should be durable and effective in removing contaminants. Quality filters lead to better performance.

- Aanpassingsopties: Some businesses have specific needs. A good supplier should provide customization options. This allows the buyer to choose the size, material, and type of filter that fits their requirements.

- After-Sales Service: After-sales service is crucial. A reliable supplier should offer support after the sale. This includes help with installation, maintenance, and any issues that may arise.

- Naleving van industrienormen: The supplier must comply with industry standards. This means their products should meet safety and performance guidelines. Compliance ensures that the filters are safe and effective for use.

These factors help businesses make informed choices when selecting a bag filter supplier.

Applications of Bag Filters in Various Industries

Bag filters have many uses in different industries. They help to clean the air and protect the environment. Here are some industries that use bag filters and how they apply them:

| Industrie | Applications of Bag Filters |

| Elektriciteitscentrales | Remove dust and pollutants from exhaust gases. |

| Steel Manufacturing | Capture metal dust and fumes during production. |

| Cementproductie | Control dust from grinding and mixing processes. |

| Voedselverwerking | Filter air and maintain hygiene in production areas. |

| Chemical Industry | Collect harmful particles and improve air quality. |

| Farmaceutica | Ensure clean air in labs and production sites. |

In power plants, bag filters work to clean the air by removing dust and harmful gases. This helps to keep the air fresh and safe for people living nearby.

In steel manufacturing, bag filters capture dust and fumes that come from making steel. This keeps the workplace safer for workers and reduces pollution. Cement production also uses bag filters to control dust. When making cement, a lot of dust can be created. Bag filters help to manage this dust and keep the air clean.

Food processing facilities use bag filters to filter air. Clean air is important for making safe food products. Bag filters help to maintain hygiene in these places.In the chemical industry, bag filters collect harmful particles. This improves air quality, making it safer for workers and the environment.

Pharmaceutical companies use bag filters to ensure clean air in labs. This is crucial for making medicines that are safe for people to use.

Technological Advancements in Bag Filter Systems

Technological advancements in bag filter systems make them better and more efficient. These advancements help industries filter air and liquids more effectively. Here are some recent improvements:

- Improved Filtration Materials: New materials like nanofibers and advanced polymers help catch smaller particles. These materials last longer and improve air quality.

- Automatisering: Many bag filter systems now use smart technology. This technology can monitor performance and adjust settings automatically. It saves time and reduces human error.

- Energie-efficiëntie: New designs make bag filters use less energy. This helps industries save money on energy costs while still getting good filtration results.

- Compact Designs: Modern bag filter systems are smaller and easier to install. This saves space in factories and makes maintenance simpler.

- Enhanced Cleaning Processes: New cleaning techniques help keep filters working longer. They reduce downtime and improve overall efficiency.

These advancements show how bag filter systems are evolving to meet the needs of different industries.

Environmental and Health Benefits of Efficient Bag Filters

Efficient bag filters offer many benefits for the environment and health. They help clean the air and keep it safe for everyone. Here are some key benefits:

- Reduced Air Pollution: Efficient bag filters trap dust and harmful particles. This process lowers the amount of pollution released into the air. Cleaner air leads to better health for people and wildlife.

- Improved Respiratory Health: When bag filters work well, they remove allergens and pollutants from the air. This helps people breathe easier and reduces issues like asthma and allergies.

- Compliance with Environmental Regulations: Many countries have rules to limit air pollution. Efficient bag filters help companies meet these rules. This means that businesses can operate without harming the environment.

- Less Waste Generation: These filters can capture and contain waste materials. This means less waste goes into landfills. It also helps in recycling materials, which is better for the planet.

- Energie-efficiëntie: Efficient bag filters can save energy. When air systems run smoothly, they use less energy. This can lower energy costs and reduce the carbon footprint of buildings.

- Better Indoor Air Quality: Efficient bag filters not only clean outdoor air but also improve indoor air quality. This makes homes and workplaces healthier places to be, leading to happier and more productive lives.

Conclusie

Selecting the right bag filter supplier and manufacturer is very important. A good supplier provides high-quality filters. Quality filters help industries run better and more efficiently. When operations are efficient, companies save money and time. This leads to better productivity and results.

It is essential to consider filtration needs carefully. Companies should look for suppliers with a good reputation. These suppliers understand the industry’s needs and offer the best solutions. The right choice can make a big difference in overall performance.

Readers should assess their filtration needs. They should consult with reputable suppliers. Doing this will help ensure they get the best bag filters for their operations.