부엌

본사

독일

- Intensiv 필터 Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, 독일/독일 - +49 20534200990

지역 사무소

대 브리튼 섬

- Intensiv Filter Himenviro UK Limited

47, Bath Street WS13BX, 월솔 웨스트 미들랜드, 영국 - +44 1922 628893

지역 사무소

아랍에미리트

- 집중 필터 Himenviro Technologies FZE – LLC

비즈니스 센터, 샤르자 출판 도시 자유무역지구, 샤르자, UAE - +971-556074697

지역 사무소

인도

- 인텐시브-필터 히멘비로 프라이빗 리미티드

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

지역 사무소

인도

- 인텐시브-필터 히멘비로 프라이빗 리미티드

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

지역 사무소

인도

- 인텐시브-필터 히멘비로 프라이빗 리미티드

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

식품 산업 공기 및 먼지 여과 솔루션

식품 및 음료 산업 정밀한 공정과 엄격한 위생 기준에 의존하는 복잡하고 규제가 엄격한 분야입니다. 이러한 기준을 유지하는 데 중요한 요소 중 하나는 효과적인 분진 관리입니다. 곡물 취급, 혼합, 블렌딩, 포장 등의 공정은 미세 분진 입자를 발생시켜 제품을 오염시키고, 작업자의 건강을 위협하며, 잠재적인 폭발 위험을 초래할 수 있습니다.

이러한 과제를 해결하기 위해 우리는 고급 서비스를 제공합니다. 여과 솔루션 식음료 산업을 위해 특별히 설계되었습니다. 당사 시스템은 먼지 입자를 포집하고 제거하도록 설계되어 제품 순도, 작업자 안전 및 규정 준수를 보장합니다.

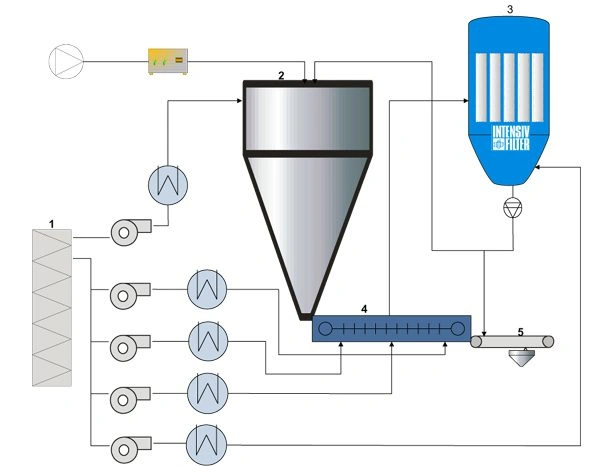

식품 산업의 먼지 여과 공정

1

외부 필터

2

분무 건조기

3

CIP필터

4

외부 유동화 침대

5

충전재

- 1. 외부필터

- 2. 분무 건조기

- 3. CIP필터

- 4. 외부 유동화층

- 5. 채우기

CIP 필터에 필요한 사양

일반적인 설계 데이터 | CIP필터 |

|---|---|

가스량 | < 230,000m³/h |

가스 온도 | 80~90°C |

먼지의 종류 | 분유제품 |

잔류먼지 함량 | < 10g/m³ |

원료가스 분진 함량 | 20mg/m³ |

청소 | 온라인 |

필터 매체 | 폴리에스터 |

폭발 정격 설계 | 예 |

흡착제 |

식품 산업을 위한 당사 제품 응용 분야

먼지 제어를 위한 규제 환경 |

|---|

식품 안전 규정 |

FDA 및 USDA 표준 준수 |

근로자 건강 및 안전 |

OSHA 규정 준수 |

화재 및 폭발 예방 |

NFPA 표준 구현 |

환경 보호 |

제품 품질 및 일관성 |

가동 중지 시간 및 유지 관리 비용 감소 |

먼지 제어 과제 |

|---|

제품 오염 |

근로자 건강 위험 |

화재 및 폭발 위험 |

규정 준수 |

교차 오염 |

미생물 성장 |

엄격한 식품 안전 준수 |

제품 품질 저하 |

장비 손상 |

효과적인 먼지 제어를 위한 주요 고려 사항 |

|---|

효과적인 먼지 포집 구현 |

적절한 공기 흐름과 압력을 확보하세요 |

분유제품 |

고효율 여과 시스템을 활용하세요 |

정기적인 유지관리 및 검사 |

산업 표준을 준수합니다 |

정기적으로 먼지 제어 시스템을 평가하세요 |

프로세스별 고려 사항 |

위험 평가 및 완화 |

전문가 상담을 위해 저희에게 연락하세요

다른 서비스를 살펴보세요!

식품 산업에서 분무탑 건조 플랜트는 분쇄된 제품(분유, 이유식 등)을 생산하는 데 사용됩니다.

자주 묻는 질문

식품 가공에서 일반적인 여과 시스템에는 멤브레인 필터(미세여과, 한외여과, 나노여과, 역삼투압 등), 심층 필터, 활성탄 필터, 자외선(UV) 시스템 등이 있습니다. 이러한 기술은 물리적, 화학적, 생물학적 오염물질을 제거하여 제품의 순도와 안전성을 보장하는 데 사용됩니다.

여과 시스템은 원료 및 제품에서 미생물, 미립자, 화학 잔류물 등의 오염 물질을 효과적으로 제거하여 식품 안전 기준을 준수합니다. 이러한 정제 과정은 규제 요건을 충족하고 최종 식품의 높은 품질 기준을 유지하는 데 도움이 됩니다.

여과 시스템은 원재료와 최종 제품에서 원치 않는 미립자, 미생물 및 기타 오염 물질을 제거하여 제품 품질과 일관성을 유지합니다. 이를 통해 각 배치가 원하는 순도 및 품질 기준을 충족하도록 보장하여 모든 제품의 맛, 외관 및 안전성이 균일하게 유지됩니다.

사례 연구

관련 사례 연구 읽기