부엌

본사

독일

-

Intensiv 필터 Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, 독일/독일 - +49 20534200990

지역 사무소

대 브리튼 섬

-

Intensiv Filter Himenviro UK Limited

47, Bath Street WS13BX, 월솔 웨스트 미들랜드, 영국 - +44 1922 628893

지역 사무소

아랍에미리트

-

집중 필터 Himenviro Technologies FZE – LLC

비즈니스 센터, 샤르자 출판 도시 자유무역지구, 샤르자, UAE - +971-556074697

지역 사무소

인도

-

인텐시브-필터 히멘비로 프라이빗 리미티드

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

지역 사무소

인도

-

인텐시브-필터 히멘비로 프라이빗 리미티드

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

지역 사무소

인도

-

인텐시브-필터 히멘비로 프라이빗 리미티드

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

Food Industry Air and Dust Filtration Solutions

The food and beverage industry is a complex and highly regulated sector that relies on precise processes and stringent hygiene standards. One critical aspect of maintaining these standards is effective dust control. Processes such as grain handling, mixing, blending, and packaging generate fine dust particles that can contaminate products, pose health risks to workers, and create potential explosion hazards.

To address these challenges, We offer advanced filtration solutions specifically designed for the food and beverage industry. Our systems are engineered to capture and remove dust particles, ensuring product purity, worker safety, and regulatory compliance.

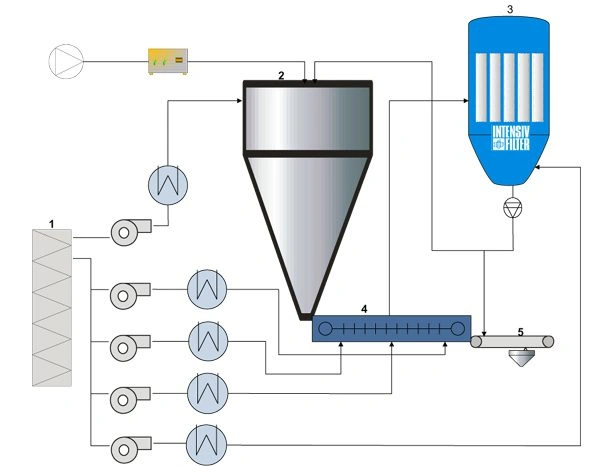

Dust Filtration Process in the Food Industry

- 1. 외부필터

- 2. 분무 건조기

- 3. CIP필터

- 4. 외부 유동화층

- 5. 채우기

Required Specification For the CIP Filter

Our Products Application for the Food Industry

Capture dust generated during the transfer of bulk materials, such as grains, powders, and flakes.

전문가 상담을 위해 저희에게 연락하세요

다른 서비스를 살펴보세요!

자주 묻는 질문

In food processing, common filtration systems include membrane filters (such as microfiltration, ultrafiltration, nanofiltration, and reverse osmosis), depth filters, activated carbon filters, and ultraviolet (UV) light systems. These technologies are employed to remove physical, chemical, and biological contaminants, ensuring product purity and safety.

Filtration systems ensure compliance with food safety standards by effectively removing contaminants, including microorganisms, particulates, and chemical residues, from raw materials and products. This purification process helps meet regulatory requirements and maintains high-quality standards in the final food products.

Filtration systems maintain product quality and consistency by removing unwanted particulates, microorganisms, and other contaminants from ingredients and final products. This ensures that each batch meets the desired purity and quality standards, leading to uniformity in taste, appearance, and safety across all products.