Кеңселер

Штаб-пәтер

Германия

- Intensiv Filter Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Велберт, Дойчланд/Германия - +49 20534200990

ОБЛЫСТЫҚ БӨЛІМ

Ұлыбритания

- Қарқынды сүзгі Himenviro UK Limited

47, Бат-стрит WS13BX, Уолсолл Вест Мидлендс, Ұлыбритания - +44 1922 628893

ОБЛЫСТЫҚ БӨЛІМ

Біріккен Араб Әмірліктері

- Қарқынды фильтр Himenviro Technologies FZE – LLC

Іскерлік орталық, Sharjah Publishing City еркін аймағы, Шарджа, БАӘ - +971-556074697

ОБЛЫСТЫҚ БӨЛІМ

Үндістан

- Intensiv-Filter Himenviro Private Limited

D-247/11, сектор-63, Ноида - 201301, Уттар-Прадеш, Үндістан - +91-120-4642-500

ОБЛЫСТЫҚ БӨЛІМ

Үндістан

- Intensiv-Filter Himenviro Private Limited

D-247/11, сектор-63, Ноида - 201301, Уттар-Прадеш, Үндістан - +91-120-4642-500

ОБЛЫСТЫҚ БӨЛІМ

Үндістан

- Intensiv-Filter Himenviro Private Limited

D-247/11, сектор-63, Ноида - 201301, Уттар-Прадеш, Үндістан - +91-120-4642-500

Тамақ өнеркәсібі ауа мен шаңды сүзу шешімдері

Тамақ және сусындар өнеркәсібі бұл нақты процестер мен қатаң гигиеналық стандарттарға негізделген күрделі және жоғары реттелетін сектор. Осы стандарттарды сақтаудың маңызды аспектілерінің бірі шаңды тиімді бақылау болып табылады. Астықты өңдеу, араластыру, араластыру және орау сияқты процестер өнімдерді ластайтын, жұмысшылардың денсаулығына қауіп төндіретін және ықтимал жарылыс қаупін тудыратын ұсақ шаң бөлшектерін тудырады.

Осы қиындықтарды шешу үшін біз озық ұсыныстарды ұсынамыз фильтрациялық ерітінділер тамақ және сусындар өнеркәсібі үшін арнайы әзірленген. Біздің жүйелер шаң бөлшектерін ұстау және жою, өнімнің тазалығын, жұмысшылардың қауіпсіздігін және нормативтік талаптарға сәйкестігін қамтамасыз ету үшін жасалған.

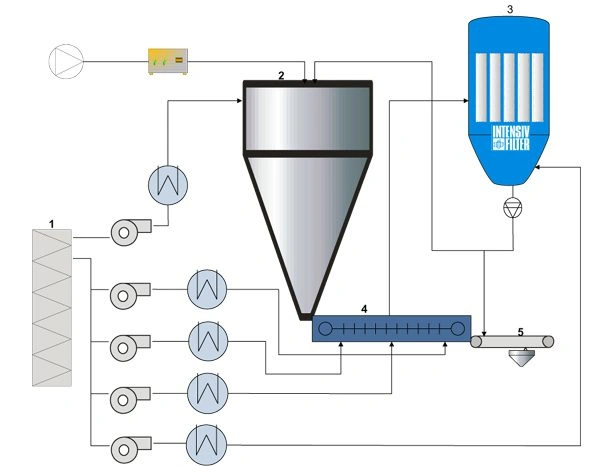

Тамақ өнеркәсібіндегі шаңды сүзу процесі

- 1. Сыртқы сүзгі

- 2. Бүріккіш кептіргіш

- 3. CIP сүзгісі

- 4. Сыртқы сұйық қабат

- 5. Толтыру

CIP сүзгісі үшін талап етілетін спецификация

Типтік дизайн деректері | CIP сүзгісі |

|---|---|

Газ көлемі | < 230 000 м³/сағ |

Газ температурасы | 80-90 °C |

Шаң түрі | Кептірілген сүт өнімдері |

Қалдық шаң мөлшері | < 10 г/м³ |

Шикі газ шаңының құрамы | 20 мг/м³ |

Тазалау | Онлайн |

Сүзгі ортасы | Полиэстер |

Жарылысқа есептелген дизайн | Иә |

Сорбент |

Біздің өнімдеріміздің тамақ өнеркәсібіне арналған қосымшасы

Дәндер, ұнтақтар және үлпектер сияқты сусымалы материалдарды тасымалдау кезінде пайда болатын шаңды ұстаңыз.

Ұнтақтау, ұнтақтау және ұнтақтау сияқты жоғары энергетикалық процестерден шаң шығарындыларын бақылаңыз.

Шаңды бақылауға арналған нормативтік ландшафт |

|---|

Азық-түлік қауіпсіздігі ережелері |

FDA және USDA стандарттарын сақтау |

Жұмысшылардың денсаулығы және қауіпсіздігі |

OSHA ережелеріне сәйкестік |

Өрт пен жарылыстың алдын алу |

NFPA стандарттарын енгізу |

Қоршаған ортаны қорғау |

Өнімнің сапасы мен жүйелілігі |

Қысқартылған тоқтап тұру және техникалық қызмет көрсету шығындары |

Шаңды бақылау қиындықтары |

|---|

Өнімнің ластануы |

Жұмысшылардың денсаулығына қатысты қауіптер |

Өрт және жарылыс қаупі |

Нормативтік талаптарға сәйкестік |

Айқас ластану |

Микробтардың өсуі |

Азық-түлік қауіпсіздігін қатаң сақтау |

Өнім сапасының төмендеуі |

Жабдықтың зақымдалуы |

Шаңды тиімді бақылауға арналған негізгі ойлар |

|---|

Шаңды тиімді ұстауды іске қосыңыз |

Тиісті ауа ағыны мен қысымды қамтамасыз етіңіз |

Кептірілген сүт өнімдері |

Жоғары тиімді сүзу жүйелерін пайдаланыңыз |

Тұрақты техникалық қызмет көрсету және тексеру |

Салалық стандарттарды ұстаныңыз |

Шаңды бақылау жүйесін үнемі бағалаңыз |

Процесті арнайы қарастырулар |

Тәуекелді бағалау және азайту |

Мамандық кеңес алу үшін бізбен байланысыңыз

Біздің басқа қызметтерімізді зерттеңіз!

Жиі қойылатын сұрақтар

Тамақ өнімдерін өңдеуде кең таралған сүзу жүйелеріне мембраналық сүзгілер (микрофильтрация, ультрафильтрация, нанофильтрация және кері осмос сияқты), тереңдік сүзгілері, белсендірілген көмір сүзгілері және ультракүлгін (УК) жарық жүйелері кіреді. Бұл технологиялар өнімнің тазалығы мен қауіпсіздігін қамтамасыз ететін физикалық, химиялық және биологиялық ластаушы заттарды жою үшін қолданылады.

Сүзу жүйелері ластаушы заттарды, соның ішінде микроорганизмдерді, бөлшектерді және химиялық қалдықтарды шикізат пен өнімдерден тиімді жою арқылы тамақ өнімдерінің қауіпсіздігі стандарттарының сақталуын қамтамасыз етеді. Бұл тазарту процесі нормативтік талаптарды орындауға көмектеседі және соңғы тамақ өнімдерінде жоғары сапа стандарттарын сақтайды.

Сүзу жүйелері ингредиенттер мен соңғы өнімдерден қажетсіз бөлшектерді, микроорганизмдерді және басқа ластаушы заттарды кетіру арқылы өнімнің сапасы мен консистенциясын сақтайды. Бұл әрбір топтаманың қажетті тазалық пен сапа стандарттарына сай болуын қамтамасыз етеді, бұл барлық өнімдерде дәм, сыртқы көрініс және қауіпсіздік бойынша біркелкілікке әкеледі.