Electrostatic Precipitators (ESPs) are at the heart of industrial air pollution control systems — providing unmatched dust collection efficiency for industries that generate particulate emissions from combustion, smelting, or manufacturing processes. Whether it’s fly ash from power plants, clinker dust from cement kilns, or metal fumes from foundries, ESPs play a vital role in meeting emission standards, improving workplace safety, and ensuring environmental sustainability.

A Filtro intensivo Himenviro, we design, manufacture, and maintain advanced ESP systems tailored to industrial operations across the world. This guide explains where ESPs are used, why they’re chosen, the performance data that matters, and how Intensiv-Filter Himenviro helps B2B clients achieve long-term compliance and efficiency.

Quick Summary for Decision-Makers

Electrostatic Precipitators are extensively used in:

- Coal- and biomass-fired power plants

- Cement production facilities

- Steel, iron, and non-ferrous metal smelting units

- Petroleum refining and petrochemical industries

- Pulp & paper recovery boilers

- Municipal and hazardous waste incinerators

- Glass, ceramic, mineral, and chemical manufacturing processes

Modern ESPs regularly achieve >99% collection efficiency, effectively reducing dust, smoke, and fly ash levels to below 10 mg/Nm³. For industries handling very large gas volumes or operating at high temperatures, ESPs remain the most energy-efficient and durable emission control solution available.

Industries and Applications

1. Power Generation (Utility & Captive Plants)

Coal and biomass-fired boilers produce vast volumes of fly ash and fine particulates that can severely impact air quality. ESPs have been the global standard in this sector for decades due to their ability to handle massive flue gas volumes (up to millions of m³/hr) with low pressure drop and minimal energy consumption.

- Efficienza: >99.5% collection rate

- Emission levels: As low as <10 mg/Nm³

- Vantaggi: Long operational life, minimal maintenance, and adaptability to retrofit programs for older power units.

At Intensiv-Filter Himenviro, our ESPs are customized to maintain consistent performance under variable loads, fuel compositions, and operating temperatures, ensuring continuous compliance and lower lifecycle costs.

2. Cement Plants

Cement manufacturing is one of the most dust-intensive industrial processes. Clinker coolers, kilns, and coal mills generate exhaust gas containing heavy dust loads—often exceeding 100–200 mg/Nm³ before filtration.

Our ESPs are designed to handle high temperatures (up to 400°C) E abrasive dust conditions typical in cement production, achieving emission levels below 20 mg/Nm³ without significant pressure loss.

Applications include:

- Kiln and raw mill exhaust filtration

- Cooler and clinker dust collection

- Coal mill gas cleaning and pre-filtration before baghouses

This ensures sustainable operations while meeting environmental norms and enhancing heat recovery performance.

3. Steel, Foundry & Metal Processing

From sinter plants to blast furnaces, steel and metallurgical industries generate high concentrations of metallic and abrasive dust particles. ESPs efficiently capture iron oxide, zinc, and other metallic fumes with collection efficiencies above 98–99%.

Typical use cases include:

- Sinter plant exhaust gas filtration

- Basic oxygen furnace (BOF) and electric arc furnace (EAF) off-gas cleaning

- Non-ferrous metal smelter emissions

Intensiv-Filter Himenviro ESPs are built to endure harsh operational environments, with rugged electrodes, effective rapping mechanisms, and corrosion-resistant components to maximize uptime and reliability.

4. Petroleum Refining & Petrochemicals

Refineries and petrochemical units use ESPs to remove fine catalyst dust and coke particles from flue gas streams — especially in Fluid Catalytic Cracking (FCC) units and coke calcining processes.

Key benefits:

- Operates reliably at temperatures up to 450°C

- Handles sticky and corrosive dust streams

- Reduces emissions to below 10 mg/Nm³

Our ESP solutions integrate with refinery control systems to ensure continuous monitoring, minimal downtime, and optimized energy usage.

5. Pulp & Paper (Recovery Boilers and Lime Kilns)

Recovery boilers in paper mills produce fine fly ash and condensed solids during the black liquor burning process. ESPs remove up to 99.7% of these particles, ensuring stack emissions remain below 30 mg/Nm³.

At the same time, ESPs recover valuable materials like sodium salts, improving process efficiency and resource recovery. This dual advantage of pollution control + material recycling makes ESPs indispensable in pulp and paper industries.

6. Waste Incineration (Municipal & Hazardous Waste)

Incinerators produce complex flue gases containing fly ash, heavy metals, and dioxins. ESPs form the first-stage filtration system, effectively capturing 90–95% of solid particulates, while downstream bag filters or scrubbers handle finer pollutants.

In multi-stage configurations (ESP + fabric filter + wet scrubber), emissions can be reduced to below 5 mg/Nm³, meeting the most stringent environmental norms worldwide.

7. Other Process Industries

ESPs are also widely used in:

- Food and grain drying (to prevent product loss)

- Glass manufacturing (to handle high-temperature silica dust)

- Ceramic and mineral industries (for coarse dust collection)

- Chemical and fertilizer plants (for catalyst and fume recovery)

Their versatility, scalability, and adaptability make ESPs suitable for nearly any industrial process with particulate emissions.

Why Industrial Buyers Choose ESPs — Data & Performance Insights

1. High Collection Efficiency

Modern ESPs achieve 95–99.9% efficiency, depending on the particulate type, particle resistivity, and electrical field design. They are particularly effective for handling large gas volumes at a low cost per cubic meter treated.

2. Handles Large Gas Volumes & High Temperatures

ESPs operate effectively in gas flows exceeding 1,000,000 m³/hr and temperatures up to 450°C, making them ideal for heavy-duty industrial operations.

3. Low Pressure Drop & Energy Efficiency

With typical pressure drops between 100–250 Pa, ESPs reduce fan energy consumption compared to fabric filters. Even though ESPs use high-voltage systems, the total operational power cost is generally lower for large-scale applications.

4. Minimal Maintenance

Modern ESPs offer 95%+ uptime, with periodic maintenance focused mainly on transformer/rectifier units and rapping systems. Intensiv-Filter Himenviro provides predictive maintenance tools and spare part support for consistent reliability.

5. Market Growth & Regulatory Demand

The global ESP market was valued between USD 7.6 to 9.1 billion in 2024, with a projected CAGR of 3–6% (2025–2032).

The growth is driven by:

- Tightening emission regulations across Asia, Europe, and the Americas

- Rapid industrialization in emerging economies

- Transition towards hybrid and digitalized emission control systems

Design Considerations for Procurement & Project Teams

When selecting or upgrading an Electrostatic Precipitator (ESP), industrial decision-makers must carefully assess key parameters that impact performance, compliance, and cost efficiency.

- Target Emission Limit (mg/Nm³):

Defines whether a single- or multi-stage ESP is needed. Stricter limits (below 20 mg/Nm³) require multi-field, high-voltage designs for maximum dust collection efficiency. - Caratteristiche della polvere:

Particle size, resistivity, and composition determine electrode design and material choice. Fine or sticky dusts may need special configurations to maintain efficiency. - Gas Flow & Temperature:

Gas volume and temperature (typically 120°C–400°C) influence plate spacing, electrical load, and material selection for long-term durability. - Footprint & Retrofit Constraints:

Space limitations demand compact, modular ESPs for easy integration into existing setups with minimal downtime.

Operational Costs (OPEX):

Monitoring T/R unit power, rapping frequency, and ash handling affects running costs. Advanced ESPs can lower energy use by 15–20% through intelligent controls.

Automation & Compliance:

Integration with PLC/SCADA enables real-time tracking, emission reporting, and predictive maintenance, ensuring reliable performance and regulatory compliance.

Ensure Clean Air and Regulatory Compliance Today

Typical Performance Benchmarks

| Parametro | Industry Average | Intensiv-Filter Himenviro ESPs |

|---|---|---|

| Efficienza della raccolta | 95–99.9% | Up to 99.9% |

| Temperatura di esercizio | Up to 450°C | Up to 480°C |

| Caduta di pressione | 100–250 Pa | 100–200 Pa |

| Outlet Emission | <30 mg/Nm³ | <10 mg/Nm³ |

| Uptime | 90–95% | >98% |

Intensiv-Filter Himenviro Advantage

With more than 100+ years of combined filtration expertise, Intensiv-Filter Himenviro provides turnkey ESP systems, retrofit services, and aftermarket solutions that deliver guaranteed compliance, efficiency, and longevity.

We Offer:

- Customized ESP Design & Manufacturing

Tailored for your gas flow, dust load, and temperature range. - Retrofit & Modernization Services

Replace old electrodes, upgrade T/R systems, and integrate automation for better efficiency. - Guaranteed Performance

Compliance assurance for inlet/outlet emission levels. - 24/7 Support & Global Spare Supply

Fast delivery of electrodes, rappers, and control components. - Digital Commissioning & Monitoring

Real-time stack monitoring and predictive diagnostics.

Real-World Performance Case

A 200 MW coal-fired power plant processing 500,000 m³/hr of flue gas with an inlet dust concentration of 300 mg/Nm³ installed a modern Intensiv-Filter Himenviro ESP system.

Post-commissioning results:

- Outlet emission: <10 mg/Nm³

- Energy savings: 12% reduction in fan power usage

- Payback period: <2 years through OPEX savings and regulatory incentives

This project demonstrated how ESP retrofits not only ensure compliance but also deliver measurable operational and financial benefits.

ESPs vs Fabric Filters vs Hybrid Systems

| Parametro | Precipitatore elettrostatico | Fabric Filter (Baghouse) | Hybrid System |

|---|---|---|---|

| Intervallo di temperatura | Up to 450°C | Up to 260°C | Up to 400°C |

| Caduta di pressione | Basso | Moderate–High | Moderare |

| Efficienza | 95–99.9% | 99.9%+ | 99.95%+ |

| Manutenzione | Basso | Moderate (bag replacement) | Moderare |

| Il migliore per | Large gas volumes, abrasive dust | Fine dust, low gas flow | Multi-pollutant control |

Ready to Evaluate or Retrofit?

If you’re a plant head, procurement manager, or project consultant, here’s how you can start:

- Share Your Process Data Sheet: Include gas composition, flow, dust load, and temperature.

- Get a Tailored Proposal: We’ll deliver emission guarantees, energy analysis, and cost breakdown.

- Optional On-Site Audit: Evaluate retrofit potential and ROI before investment.

Final Word

Electrostatic Precipitators continue to be the backbone of industrial emission control, combining efficiency, scalability, and reliability. With tightening environmental norms and rising energy costs, a modern ESP solution from Intensiv-Filter Himenviro ensures compliance, cost-effectiveness, and operational excellence for decades to come.

Scopri la nostra gamma di soluzioni:

Domande frequenti

An Electrostatic Precipitator (ESP) is an advanced air pollution control device used to remove fine dust particles, fumes, and smoke from industrial exhaust gases. It uses electrical forces to charge and collect particulate matter, achieving dust collection efficiencies of up to 99.9%, depending on design and process conditions. ESPs are widely used in industries like cement, steel, power generation, chemicals, and pulp & paper to maintain clean emissions and comply with environmental norms.

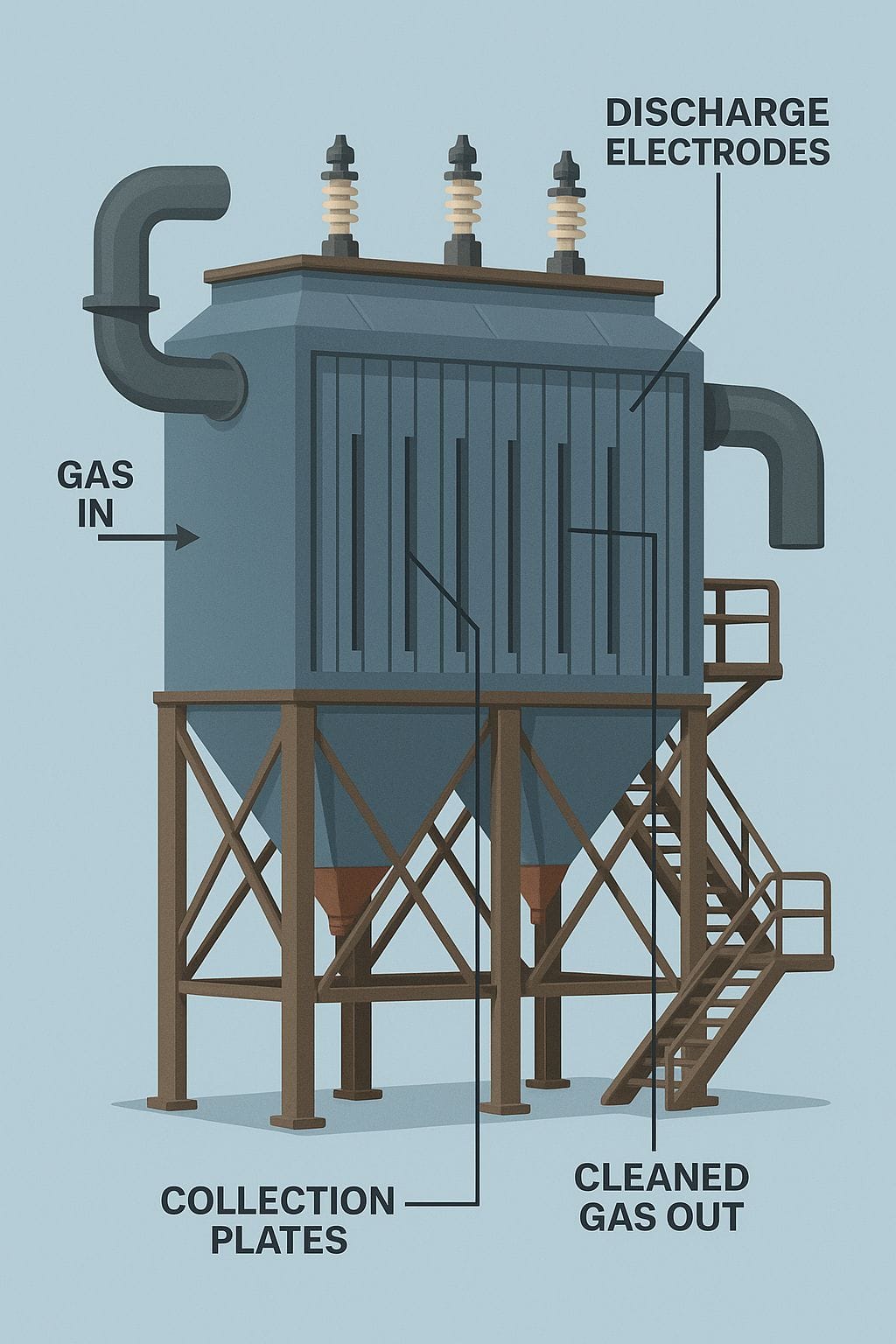

An ESP works by passing flue gas through electrically charged plates and discharge electrodes. Dust particles get ionized, gaining an electric charge. These charged particles are then attracted to oppositely charged collecting plates, where they accumulate. Periodically, rapping mechanisms shake the plates to dislodge collected dust, which falls into hoppers for safe disposal or reuse.

Modern ESPs achieve 95–99.9% collection efficiency, depending on gas composition, dust properties, and design (number of fields, plate spacing, and voltage). Multi-field ESPs can reduce emissions to below 20 mg/Nm³, meeting the latest industrial air quality standards.

Typical issues include high-resistivity dust, uneven gas distribution, corona suppression, rapping re-entrainment, and electrical insulator failures. However, with proper design optimization, regular maintenance, and PLC-based automation, these challenges can be effectively minimized.