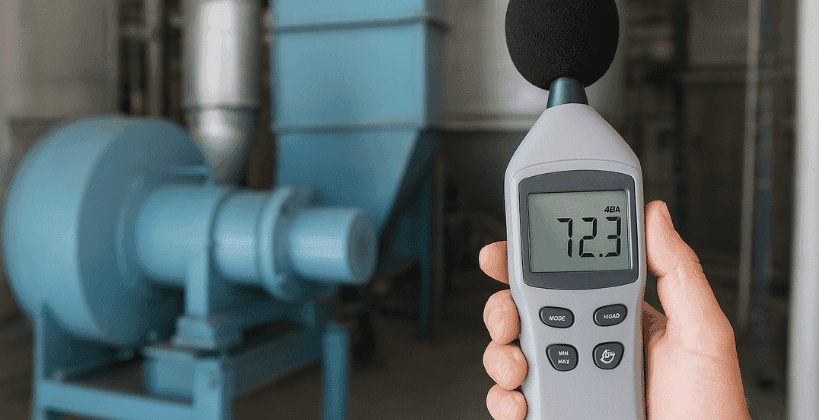

Noise has always been an inseparable part of industrial operations. From the constant hum of fans to the mechanical vibrations of dust collectors, industrial noise is often treated as a “background element” rather than a measurable risk. However, excessive noise exposure is one of the leading causes of workplace fatigue, stress, and even long-term hearing damage. Beyond employee health, industrial noise also affects community relations, environmental compliance, and the overall acceptance of a facility’s operations.

Recognizing these challenges, the German Institute for Standardization (DIN) developed the DIN 45635 standard—a framework that defines how industrial noise should be measured, evaluated, and reported. This standard provides a consistent and scientifically validated approach to understanding the acoustic footprint of machines, ensuring that manufacturers and operators have reliable data for compliance and optimization.

For Filter Intensif Himenviro, a global provider of dust collection and gas cleaning technologies, DIN 45635 compliance is an integral part of engineering philosophy. Their solutions are designed not only to control dust and emissions but also to ensure safe, sustainable, and quieter workplaces.

What is DIN 45635?

The DIN 45635 standard establishes uniform procedures for determining noise emissions from machinery under controlled conditions. Its primary goal is to create a common language for manufacturers, regulators, and operators when it comes to machine noise.

The standard covers three critical aspects:

- Sound Power Level Determination – It specifies how to calculate the sound power output of machinery, ensuring that data from different manufacturers is comparable.

- Measurement Environments – DIN 45635 defines the acoustic conditions needed for accurate noise testing, minimizing the influence of external factors.

- Compliance Limits – It sets benchmarks that protect workers from excessive noise exposure and help industries stay compliant with occupational health regulations.

By providing these guidelines, DIN 45635 ensures that noise measurement is not subjective but standardized, measurable, and enforceable.

Why Noise Measurement Matters in Industry

Noise in industrial facilities is more than just an inconvenience—it is a critical occupational hazard. High noise levels can impair concentration, reduce communication efficiency, and lead to permanent hearing damage if left unaddressed.

Key reasons why noise measurement is vital include:

- Worker Health & Safety: Prolonged exposure to noise above permissible levels can cause irreversible hearing loss, fatigue, and stress.

- Kepatuhan terhadap Peraturan: Many European and international occupational safety laws reference DIN 45635 or related standards for permissible noise levels.

- Operational Reliability: Excessive noise often indicates inefficiencies such as vibration, mechanical imbalance, or airflow disruptions. Measuring noise helps identify and resolve these issues early.

- Tanggung Jawab Lingkungan: Industrial facilities are increasingly monitored for noise emissions in surrounding communities. Compliance helps avoid complaints and penalties.

In industries where equipment like dust collectors, blowers, and filters run continuously, DIN 45635 compliance ensures that noise is minimized without compromising performance.

Testing Procedures under DIN 45635

To ensure accuracy, DIN 45635 outlines strict testing procedures that manufacturers must follow:

- Controlled Acoustic Environment: Tests are performed in semi-anechoic or standardized test rooms to eliminate external noise interference.

- Microphone Placement: Sound is measured at specific distances and positions around the equipment to capture an accurate sound power profile.

- Operational States: Machines are tested under different load conditions (idle, partial load, and full load) to simulate real-world performance.

- Data Evaluation: Measurements are averaged, corrected for background noise, and compared against permissible thresholds.

These rigorous procedures ensure that published noise levels are both reliable and repeatable, giving operators confidence when selecting compliant equipment.

Intensiv Filter Himenviro and DIN 45635 Compliance

Filter Intensif Himenviro has long recognized that noise is not simply a by-product of industrial processes but a factor that directly affects worker well-being and plant performance. By engineering systems with DIN 45635 standards in mind, the company provides solutions that are:

- Noise-Optimized: Careful selection of fans, filter housings, and airflow designs minimizes turbulence and reduces mechanical noise.

- Durable & Reliable: Quieter systems are often more stable, with reduced wear and vibration—leading to longer equipment life.

- Workplace-Friendly: Lower noise levels improve employee comfort, concentration, and long-term health outcomes.

- Regulatory-Ready: With built-in compliance, operators can avoid costly retrofits, audits, and downtime.

Products such as Reverse Air Bag Houses, Fabric Filters, and Electrostatic Precipitators are not only designed for dust control but also tested to meet strict noise benchmarks, offering a complete air quality and acoustic management solution.

Benefits Beyond Compliance

For many operators, compliance with DIN 45635 is the minimum requirement. However, companies that prioritize noise management gain strategic advantages:

- Improved Productivity: Quieter work environments reduce distractions and fatigue.

- Competitive Edge: Demonstrating compliance with international standards enhances customer trust and global market access.

- Sustainability Goals: Reducing noise contributes to broader corporate responsibility programs focused on environmental, social, and governance (ESG) principles.

- Future-Proof Operations: With evolving regulations and stricter limits, early adoption of noise-reduction technologies ensures long-term readiness.

Kesimpulan

Itu DIN 45635 standard is more than a guideline—it is a framework for building safer, quieter, and more sustainable industrial workplaces. Defining how noise should be measured and reported empowers manufacturers and operators to address one of the most overlooked occupational hazards.

For Filter Intensif Himenviro, adherence to DIN 45635 is not simply about meeting regulations; it is a reflection of the company’s broader mission to deliver high-performance dust collection systems that protect both people and the environment. By integrating noise control into every stage of product design, the company continues to set benchmarks for reliability, safety, and sustainability in industrial air filtration.