We often think of dust simply as debris on surfaces, but in industrial settings, it’s a critical hazard hidden in plain sight. Whether you’re running a cement kiln, metal foundry, or pharmaceutical line, dust can silently damage equipment, jeopardize product quality, and threaten worker health. And when inhalable particles exceed 10 mg/m³, regulations from authorities like the EPA, EU IED, or CPCB raise immediate red flags.

That’s why modern dust collection systems are no longer just compliance tools.

They’re mission-critical assets that drive efficiency, protect lives, and future-proof operations. They form a vital bridge between cleaner air, regulatory confidence, and operational excellence across the globe.

What Most Articles Miss: Designing for Real Industrial Challenges

Most guides cover system types and filter efficiency, but few dive into operational nuances—like handling moisture-laden dust in biomass plants, explosive dust in carbon black production, or high-temperature exhaust from cement kilns. At Intensiv Filter Himenviro, our systems are engineered to match your specific dust profile: from particle size and hygroscopic behavior to explosive risk and thermal resistance, making them far more reliable and effective than generic systems.

This granular approach not only improves air quality but reduces the total lifecycle cost of ownership by minimizing wear, optimizing cleaning cycles, and extending filter media life.

Temukan Berbagai Solusi Kami:

Types of Systems & Where They Shine

- Cyclone Pre-Separators – Best suited for bulk dust removal before fine filtration units. Cyclones use centrifugal force and are common in cement, minerals, and wood processing industries.

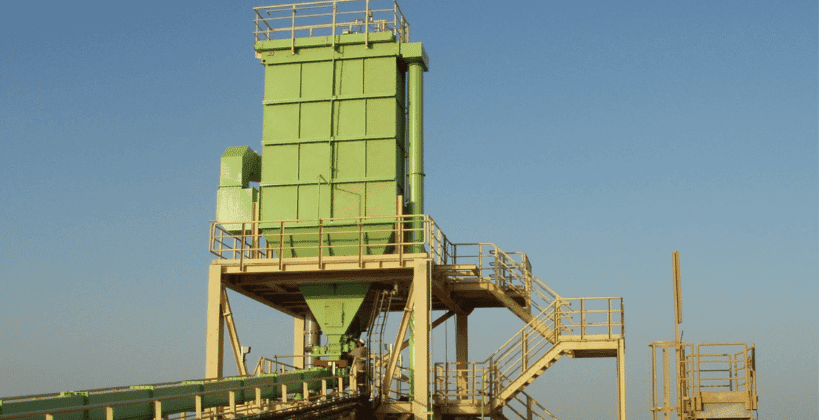

- Baghouse Filters- These are the heavy-duty champions, removing up to 99.9% of particles down to 1 micron. They’re used worldwide in cement, power, food, and metal industries for high airflow capacities and rugged dust environments.

- Cartridge Filters –Compact and ideal for fine, dry dust. Their pleated surface provides more filtration area, and they’re widely used in pharmaceutical, aerospace, and precision electronics environments.

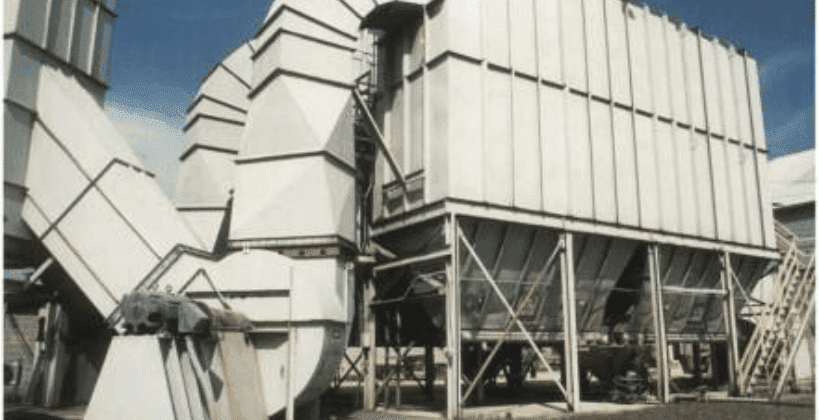

- Electrostatic Precipitators (ESPs) –Best for ultra-fine particles (< 0.01 µm). These use electrostatic attraction to collect particles from large flue gas volumes in power plants and steel mills.

- Wet Scrubbers & Venturi Systems –Perfect for sticky or corrosive dust. These systems use liquid to remove particulates and are essential in chemical manufacturing and waste incineration.

Design Details That Make the Difference

This is where Intensiv Filter Himenviro systems stand apart:

- Pressure Drop Optimization: Engineered airflow systems maintain consistent fan performance, even at high dust loads.

- Jaminan Kepatuhan: Designed to meet EPA, OSHA, EU IED, CPCB, and other regulatory frameworks globally.

- Explosion Protection: NFPA-compliant spark arrestors, isolation valves, and explosion relief panels are built into systems where needed.

- Smart Cleaning: Pulse-jet systems clean filters without halting operation, maximizing uptime.

- Advanced Media Selection: Choose from aramid, fiberglass, ePTFE, PPS, and nanofiber-based media for high-temp and corrosive conditions.

- IoT Integration: Cloud-based monitoring tools allow plant managers to track pressure drop, emissions, and filter status remotely, enabling predictive maintenance and optimized filter replacement.

- Modular Designs: Future scalability and reduced downtime during upgrades.

Presipitasi Elektrostatik

Performance Benefits That Matter

A properly designed dust collection system can radically transform industrial operations. Here’s what a world-class system delivers:

- Efficiency Gains: Lower resistance equals lower fan energy use, resulting in up to 30% energy savings.

- Health Protection: Reduces PM2.5 and PM10 levels to within occupational safety limits, improving workforce health outcomes.

- Compliance Confidence: Emission levels remain well within required standards (even <5 mg/Nm³ for urban/sensitive zones).

- Asset Longevity: Clean air reduces wear on motors, conveyors, sensors, and packaging equipment.

- Fewer Interruptions: Predictive maintenance tools minimize breakdowns and allow for proactive planning.

- Brand Reputation: Certified air quality systems enhance ESG scores and align with sustainability commitments.

Why Intensiv Filter Himenviro Leads the Global Market

With 100+ years of expertise and 5,000+ installations across five continents, Intensiv Filter Himenviro is a global leader in air filtration technology. Our systems are engineered to meet region-specific needs—whether it’s the extreme dust loads of Africa’s mining industry, high-moisture biomass dust in Southeast Asia, or ultra-clean environments in European pharma facilities.

Our Key Offerings Include:

Custom-designed Baghouse Systems: Airflow capacities up to 1,000,000+ m³/h.

ESPs: Ultra-low pressure loss, submicron particle removal.

Compact Filter Units: Ideal for limited-space operations.

Cyclones & Wet Scrubbers: For pre-filtration and corrosive dust management.

Remote Monitoring Solutions: IoT dashboards for emission and filter diagnostics.

Each system is backed by engineering consultation, installation support, and lifecycle servicing to ensure long-term ROI.

Final Thoughts: Clean Air is Smart Business

Dust collection isn’t just about trapping particles—it’s about enabling clean, continuous, and compliant industrial operations. As industries push for higher throughput and cleaner production, the need for efficient air filtration systems becomes non-negotiable. Intensiv Filter Himenviro designs filtration solutions that integrate seamlessly with your process, ensuring reliable performance under demanding conditions. Whether you’re scaling production, addressing stricter emission limits, or future-proofing a new facility, our systems are engineered to support long-term success—technically sound, globally compliant, and built for operational excellence.