Diaphragm valves play a pivotal role in industrial filtration and dust collection systems, particularly in pulse-jet bag filters, pneumatic conveying systems, and compressed air operations. Their primary function is to control or stop the flow of compressed air or fluid precisely, ensuring system efficiency and reliability.

A leaking diaphragm valve can significantly affect plant operations, causing reduced pulse-jet efficiency, higher energy consumption, increased maintenance requirements, and potential safety hazards. For industries operating in cement, power generation, metal processing, chemical, and pharmaceutical sectors, understanding the mechanical principles, failure modes, and solutions for diaphragm valve leakage is essential.

Intenzív Himenviro szűrő specializes in durable, high-performance diaphragm valves and replacement diaphragms engineered to withstand extreme industrial conditions. This article provides an in-depth analysis of the technical, mechanical, and operational aspects of diaphragm valve leakage, highlighting preventive and corrective measures to ensure optimal system performance.

How Diaphragm Valves Work

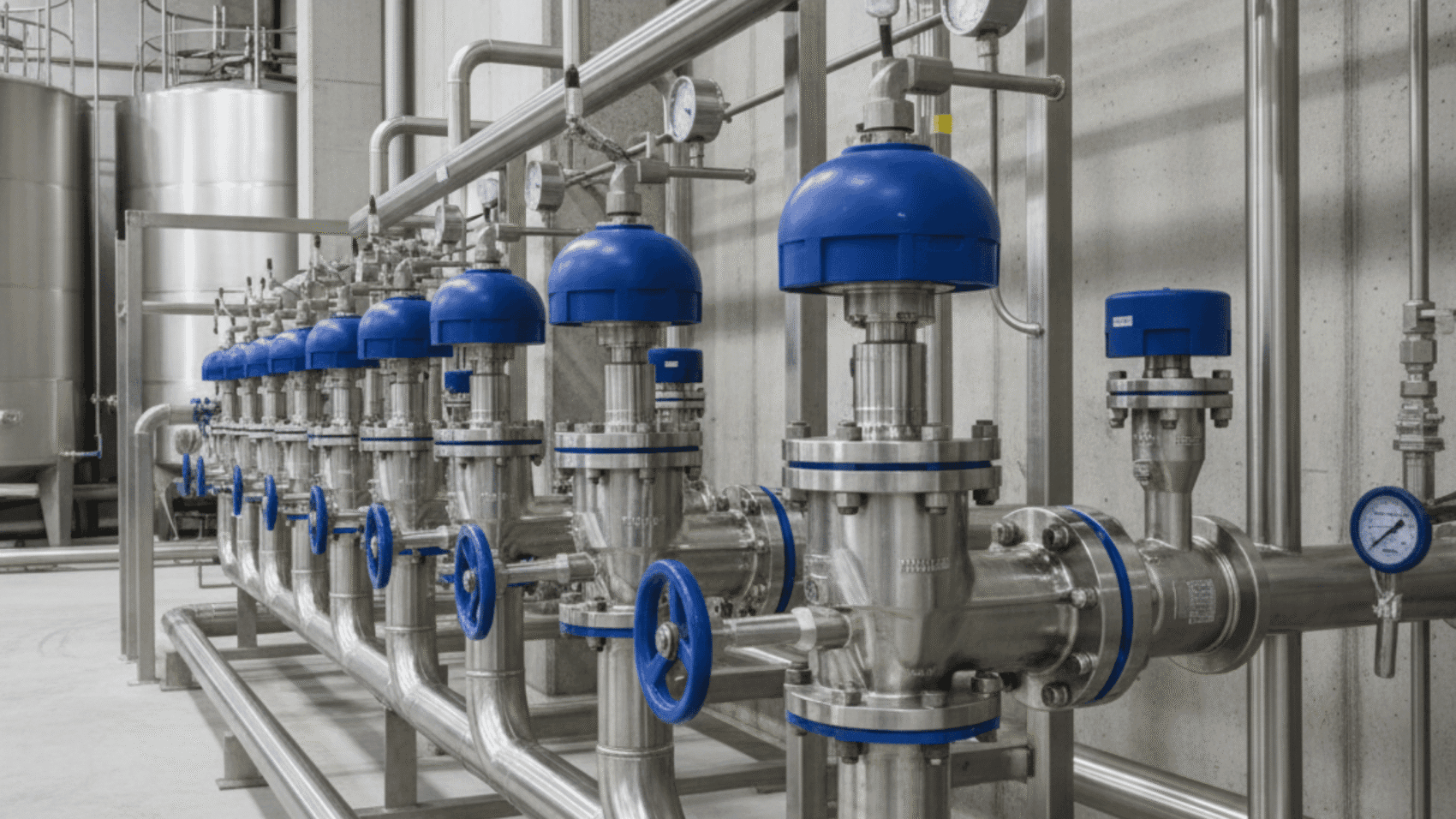

A diaphragm valve consists of a flexible membrane, a valve body, and a valve seat. When actuated by compressed air or hydraulic pressure, the diaphragm presses against the valve seat, creating a tight seal. This design eliminates direct contact between the moving parts and the process media, reducing wear and extending valve life.

In pulse-jet dust collector systems, diaphragm valves are critical for delivering high-pressure air bursts that clean filter bags. Even minor leakage can compromise cleaning efficiency, leading to particulate accumulation, higher differential pressure, reduced airflow, and accelerated filter media wear.

The performance of a diaphragm valve depends on several factors, including diaphragm material, valve seat design, operating pressure, temperature, and environmental conditions. Each parameter affects sealing integrity and the valve’s ability to maintain consistent operation under industrial conditions.

Common Causes of Diaphragm Valve Leakage

Leakage in diaphragm valves can arise from multiple mechanical, material, and operational factors. Understanding these causes is essential for effective maintenance and prevention.

1. Diaphragm Material Degradation

The diaphragm is typically made of elastomeric or reinforced synthetic materials. Over time, repeated flexing, chemical exposure, abrasive dust, and high temperatures can cause cracking, tearing, or thinning. Even small imperfections can compromise the seal, resulting in leakage and loss of system efficiency.

2. Valve Seat Wear and Corrosion

The valve seat serves as the sealing surface for the diaphragm. Continuous exposure to abrasive particles, high-velocity air, or chemically aggressive media can erode or corrode the seat, preventing a tight seal. Proper material selection and periodic inspection are crucial to maintaining valve performance.

3. Improper Installation or Misalignment

Incorrect installation, uneven diaphragm seating, or improper torque on fasteners can prevent full closure of the valve. Even minor misalignment can lead to micro-leaks, which cumulatively impact system efficiency and performance.

4. Contamination Between Diaphragm and Valve Seat

Accumulation of dust, debris, or chemically reactive particles between the diaphragm and valve seat can hinder sealing. Industrial environments with high dust loads or aggressive chemical exposure require frequent cleaning and inspection to prevent this type of leakage.

5. Excessive Operating Pressure or Temperature

Operating a diaphragm valve beyond its design specifications can overstress the diaphragm, leading to permanent deformation, blistering, or rupture. Intensiv Filter Himenviro diaphragm valves are engineered for specific pressure and temperature ranges; exceeding these limits accelerates wear and reduces service life.

Technical and Mechanical Implications of Leakage

A leaking diaphragm valve has far-reaching consequences for industrial filtration systems. Reduced pulse-jet pressure can result in incomplete cleaning of filter bags, which increases differential pressure across the system. This not only decreases airflow and filtration efficiency but also places additional load on blowers and compressors, raising energy consumption by up to 10–15% in heavily loaded systems.

Prolonged leakage can accelerate erosion and wear of filter media, resulting in higher replacement frequency and operational downtime. In chemical or pharmaceutical environments, leakage may lead to safety hazards, including exposure to toxic or corrosive gases.

From a mechanical perspective, continuous leakage increases the strain on the diaphragm and valve housing, potentially leading to premature valve failure and costly emergency maintenance.

Diagnosing and Troubleshooting Diaphragm Valve Leakage

Effective troubleshooting involves systematic inspection and technical assessment. Key steps include:

- Visual Inspection: Examine the diaphragm for cracks, tears, or thinning, and inspect the valve seat for erosion or debris accumulation.

- Pressure and Leak Testing: Conduct compressed air tests or use soap solution methods to identify micro-leaks in the valve assembly.

- Operational Monitoring: Evaluate pulse-jet pressure, airflow rates, and differential pressure across the dust collector system. Drops in expected performance may indicate valve leakage.

- Material and Environmental Analysis: Assess whether the diaphragm material is compatible with the operating temperature, chemical exposure, and dust type. Material mismatch is a frequent contributor to valve leakage.

Solutions and Maintenance Practices

Preventing or correcting diaphragm valve leakage requires a combination of high-quality components, proper installation, and routine maintenance.

Using OEM replacement diaphragms from Intensiv Filter Himenviro ensures consistent sealing performance. Our diaphragms are engineered to withstand high temperatures, chemical exposure, and heavy-duty industrial cycling, significantly reducing failure rates.

Regular preventive maintenance includes diaphragm replacement at specified intervals, valve seat inspection, and cleaning of debris to maintain optimal performance. Correct installation with precise alignment and torque specifications is essential to ensure airtight operation.

In high-temperature or chemically aggressive applications, selecting diaphragms made of thermally stable and chemically resistant materials is critical. Additionally, operating valves within the recommended pressure and temperature limits prevents overstressing the diaphragm and prolongs service life.

Advantages of Intensiv Filter Himenviro Diaphragm Valves

Diaphragm valves from Intensiv Filter Himenviro offer multiple operational advantages:

- Reliable sealing under high-frequency operation ensures effective pulse-jet cleaning.

- Extended service life due to durable, high-grade elastomeric membranes.

- Optimized design maintains consistent pulse-jet pressure, protecting filter media.

- Reduced maintenance and downtime, increasing overall system efficiency.

- Compatibility with high-temperature, high-pressure, and chemically aggressive environments.

Real-World Application Example

In a large cement plant using pulse-jet dust collectors, failing diaphragm valves caused insufficient cleaning of filter bags, resulting in a 15% increase in differential pressure and reduced airflow. After replacing OEM Intensiv Filter Himenviro diaphragms and valves, the plant observed restored pulse-jet efficiency, normalized pressure drop, and a 20% reduction in energy consumption, demonstrating the critical role of reliable diaphragm valves in industrial filtration systems.

Következtetés

Diaphragm valve leakage can significantly compromise industrial filtration efficiency, operational reliability, and safety. Understanding the mechanical, material, and operational causes of leakage is essential for effective maintenance and system optimization.

Intensiv Filter Himenviro provides high-performance diaphragm valves and replacement diaphragms engineered for demanding industrial environments. By using our solutions, industries can maintain consistent pulse-jet performance, extend filter bag life, minimize downtime, and achieve energy efficiency, while ensuring compliance with environmental and operational standards.

Fedezze fel megoldásaink kínálatát:

Gyakran Ismételt Kérdések

A diaphragm valve may leak due to diaphragm wear, cracks, or material degradation, as well as erosion of the valve seat, improper installation, or contamination preventing proper sealing.

You can identify leaks through pressure drops in the system, reduced pulse-jet cleaning efficiency, unusual hissing sounds, or visible cracks and damage to the diaphragm during inspection.

Yes. Leakage reduces the pressure and volume of compressed air released for pulse-jet cleaning, leading to poor bag cleaning, increased pressure drop, and reduced overall efficiency of the dust collection system.

The replacement interval depends on operating hours, air quality, temperature, and dust load. Typically, diaphragms last between 1–3 years in heavy-duty applications, but preventive replacement is recommended during scheduled maintenance cycles.