Mga opisina

HEADQUARTER

Alemanya

- Intensiv Filter Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Deutschland/Germany - +49 20534200990

REHIYONAL NA TANGGAPAN

Great Britain

- Intensiv Filter Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Great Britain - +44 1922 628893

REHIYONAL NA TANGGAPAN

United Arab Emirates

- Intensive Filter Himenviro Technologies FZE – LLC

Business Center, Sharjah Publishing City Free Zone, Sharjah, UAE - +971-556074697

REHIYONAL NA TANGGAPAN

India

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REHIYONAL NA TANGGAPAN

India

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

REHIYONAL NA TANGGAPAN

India

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

Mga Solusyon sa Pagsasala ng Hangin at Alikabok sa Industriya ng Pagkain

Ang industriya ng pagkain at inumin ay isang kumplikado at lubos na kinokontrol na sektor na umaasa sa mga tumpak na proseso at mahigpit na pamantayan sa kalinisan. Ang isang kritikal na aspeto ng pagpapanatili ng mga pamantayang ito ay ang epektibong pagkontrol sa alikabok. Ang mga proseso tulad ng paghawak ng butil, paghahalo, paghahalo, at pag-iimpake ay bumubuo ng mga pinong dust particle na maaaring makahawa sa mga produkto, magdulot ng mga panganib sa kalusugan sa mga manggagawa, at lumikha ng mga potensyal na panganib sa pagsabog.

Upang matugunan ang mga hamong ito, nag-aalok kami ng advanced mga solusyon sa pagsasala partikular na idinisenyo para sa industriya ng pagkain at inumin. Ang aming mga system ay ininhinyero upang makuha at alisin ang mga particle ng alikabok, tinitiyak ang kadalisayan ng produkto, kaligtasan ng manggagawa, at pagsunod sa regulasyon.

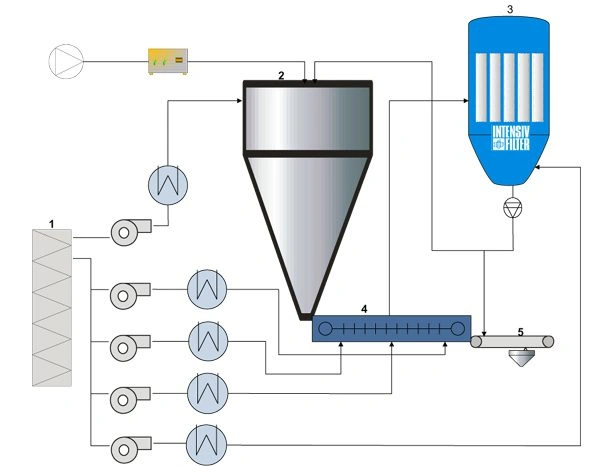

Proseso ng Pagsala ng Alikabok sa Industriya ng Pagkain

- 1. Panlabas na filter

- 2. Spray dryer

- 3. CIP filter

- 4. Panlabas na fluidized na kama

- 5. Pagpupuno

Kinakailangang Pagtutukoy Para sa CIP Filter

Karaniwang data ng disenyo | CIP filter |

|---|---|

Dami ng gas | < 230,000 m³/h |

Temperatura ng gas | 80-90 °C |

Uri ng alikabok | Mga produktong pinatuyong gatas |

Ang natitirang nilalaman ng alikabok | < 10 g/m³ |

Hilaw na nilalaman ng alikabok ng gas | 20 mg/m³ |

Paglilinis | On-line |

Filter medium | Polyester |

Disenyo na may rating ng pagsabog | Oo |

Sorbent |

Aplikasyon ng Aming Mga Produkto para sa Industriya ng Pagkain

Kunin ang alikabok na nabuo sa panahon ng paglilipat ng maramihang materyales, gaya ng mga butil, pulbos, at mga natuklap.

Kontrolin ang mga paglabas ng alikabok mula sa mga prosesong may mataas na enerhiya tulad ng paggiling, paggiling, at pagpulbos.

Regulatory Landscape para sa Dust Control |

|---|

Mga Regulasyon sa Kaligtasan ng Pagkain |

Pagsunod sa mga pamantayan ng FDA at USDA |

Kalusugan at Kaligtasan ng Manggagawa |

Pagsunod sa mga regulasyon ng OSHA |

Pag-iwas sa Sunog at Pagsabog |

Pagpapatupad ng mga pamantayan ng NFPA |

Pangangalaga sa Kapaligiran |

Kalidad at Pagkakapare-pareho ng Produkto |

Nabawasan ang downtime at mga gastos sa pagpapanatili |

Mga Hamon sa Pagkontrol ng Alikabok |

|---|

Kontaminasyon ng Produkto |

Mga Panganib sa Kalusugan ng Manggagawa |

Mga Panganib sa Sunog at Pagsabog |

Pagsunod sa Regulasyon |

Cross-contamination |

Paglago ng Microbial |

Pagsunod sa mahigpit na kaligtasan sa pagkain |

Nabawasang Kalidad ng Produkto |

Pagkasira ng Kagamitan |

Mga Pangunahing Pagsasaalang-alang para sa Mabisang Pagkontrol ng Alikabok |

|---|

Magpatupad ng epektibong pag-capture ng Alikabok |

Tiyakin ang tamang daloy ng hangin at presyon |

Mga produktong pinatuyong gatas |

Gumamit ng mga sistema ng pagsasala na may mataas na kahusayan |

Regular na Pagpapanatili at Inspeksyon |

Sumunod sa mga pamantayan ng industriya |

Regular na suriin ang sistema ng pagkontrol ng alikabok |

Mga Pagsasaalang-alang na Partikular sa Proseso |

Pagtatasa ng Panganib at Pagbabawas |

Kumonekta sa amin para sa Expert Consultation

I-explore ang Iba Naming Serbisyo!

Mga Madalas Itanong

Sa pagpoproseso ng pagkain, ang mga karaniwang sistema ng pagsasala ay kinabibilangan ng mga filter ng lamad (gaya ng microfiltration, ultrafiltration, nanofiltration, at reverse osmosis), mga depth filter, activated carbon filter, at ultraviolet (UV) light system. Ang mga teknolohiyang ito ay ginagamit upang alisin ang mga pisikal, kemikal, at biyolohikal na mga kontaminant, na tinitiyak ang kadalisayan at kaligtasan ng produkto.

Tinitiyak ng mga sistema ng pagsasala ang pagsunod sa mga pamantayan sa kaligtasan ng pagkain sa pamamagitan ng epektibong pag-alis ng mga kontaminant, kabilang ang mga mikroorganismo, particulate, at mga labi ng kemikal, mula sa mga hilaw na materyales at produkto. Ang proseso ng purification na ito ay nakakatulong na matugunan ang mga kinakailangan sa regulasyon at nagpapanatili ng mataas na kalidad na mga pamantayan sa mga huling produkto ng pagkain.

Ang mga sistema ng pagsasala ay nagpapanatili ng kalidad at pagkakapare-pareho ng produkto sa pamamagitan ng pag-alis ng mga hindi gustong particulate, microorganism, at iba pang mga contaminant mula sa mga sangkap at huling produkto. Tinitiyak nito na ang bawat batch ay nakakatugon sa nais na kadalisayan at kalidad na mga pamantayan, na humahantong sa pagkakapareho sa lasa, hitsura, at kaligtasan sa lahat ng mga produkto.