Toimistot

PÄÄKONTO

Saksa

- Intensiv Filter Himenviro Technologies GmbH

Neustraße 45-49, 42553, Velbert, Deutschland/Saksa - +49 20534200990

ALUETOIMISTO

Iso-Britannia

- Intensiv Filter Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Iso-Britannia - +44 1922 628893

ALUETOIMISTO

Yhdistyneet arabiemiirikunnat

- Intensiivinen suodatin Himenviro Technologies FZE – LLC

Business Centre, Sharjah Publishing City Free Zone, Sharjah, Arabiemiirikunnat - +971-556074697

ALUETOIMISTO

Intia

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, Intia - +91-120-4642-500

ALUETOIMISTO

Intia

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, Intia - +91-120-4642-500

ALUETOIMISTO

Intia

- Intensiv-Filter Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, Intia - +91-120-4642-500

Jätteenkäsittelyn ilman- ja pölynsuodatusratkaisut

Jätteenkäsittelyala sisältää monimutkaisia prosesseja, kuten jätteen keräämisen, siirron, käsittelyn, polttamisen ja kierrätyksen – kaikki nämä tuottavat merkittäviä määriä pölyä, haitallisia hiukkasia ja vaarallisia päästöjä. Jos näitä päästöjä ei hallita asianmukaisesti, ne aiheuttavat riskejä työntekijöiden terveydelle, määräysten noudattamiselle ja ympäristön turvallisuudelle. Edistykselliset ilman- ja pölynsuodatusratkaisumme on suunniteltu vastaamaan jätehuollon haasteisiin ja talteen ottamaan hienojakoisia hiukkasia ja epäpuhtauksia jokaisessa kriittisessä vaiheessa. Räätälöityjen järjestelmien avulla autamme jätteenkäsittelylaitoksia ylläpitämään puhtaampia työympäristöjä, vähentämään haitallisia päästöjä ja täyttämään tiukat vaatimukset. ympäristöstandardit.

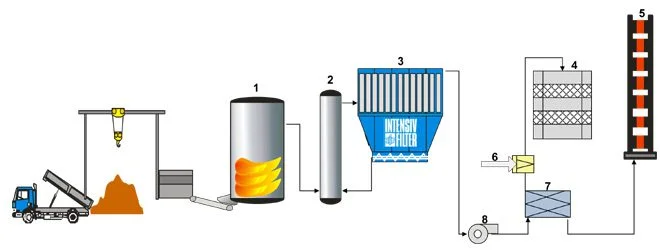

Pölynsuodatusprosessi jätteenkäsittelyteollisuudessa

Suodatin reaktoriin

- 1. Polttolaitos

- 2. Reaktori

- 3. Reaktorin suodatin

- 4. Denox-kasvi

- 5. Savupiippu

- 6. Maakaasu

- 7. Lämmönvaihdin

- 8. Tuuletin

Vaaditut tiedot

Jätteenpolton jätteiden hävitysprosessi

Tyypillisiä suunnittelutietoja | Jätteen poltto |

|---|---|

Kaasun tilavuus | 60,000-100,000 |

Kaasun lämpötila | 140-180 |

Pölyn tyyppi | Lentotuhka |

Jäännöspölypitoisuus | <10 |

Raakakaasun pölypitoisuus | 5-10 |

Puhdistus | verkossa |

Suodatinväline | |

Räjähdyssuojattu malli | ei ole tarpeen |

Sorbentti | Kalsiumhydroksidi, uunikoksi, aktiivihiili, natriumbikarbonaatti |

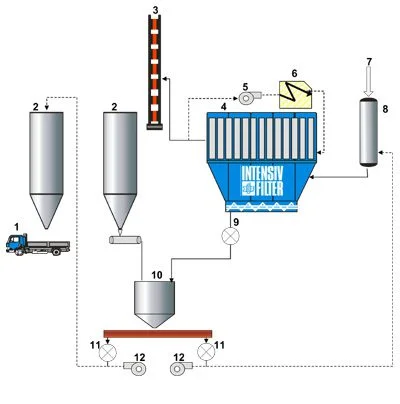

Jätevesilietteen polton jätteiden hävitysprosessi

- 1. Pääte

- 2. Siilo

- 3. Savupiippu

- 4. Reaktorin suodatin

- 5.Kiertoilmapuhallin

- 6. Lämmittimen akku

- 7. Polttolaitosten jätekaasut

- 8. Tuuletin

- 9. Vastaanotinsäiliö

- 10. Vastaanotinsäiliö

- 11. Läpipuhallusventtiili

- 12. Ilmankuivain

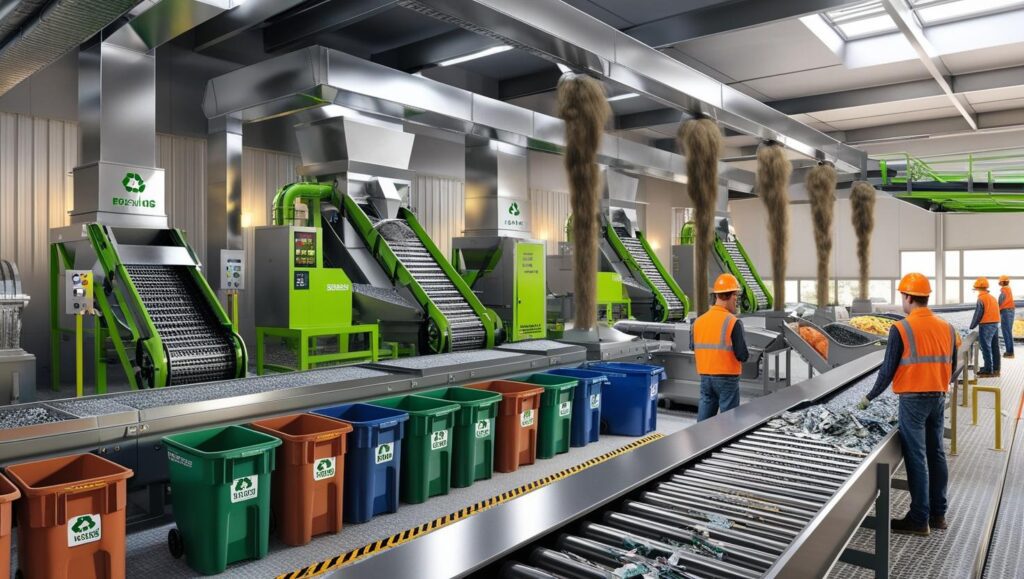

Jätteenkäsittelyn pölynhallinnan sovellukset

Hallitsee jätteenkeräyksen ja lajittelun aikana syntyvää pölyä ja minimoi ilmassa olevat hiukkaset, jotka saattavat sisältää epäpuhtauksia.

Kerää pöly- ja hajupäästöjä siirtopisteissä irtotavarajätteen siirron aikana, mikä parantaa ilmanlaatua siirtoasemilla.

Vähentää korkean lämpötilan polttolaitosten päästöjä, vähentäen hienojakoisia hiukkasia, vaarallisia kaasuja ja haitallisia sivutuotteita.

Suodattaa pölyä, jota syntyy lajittelun, silppuamisen ja kierrätyksen aikana esimerkiksi metallien, muovien ja lasin osalta.

Pölyn torjunnan sääntelymaisema |

|---|

Ilmanlaatustandardien noudattaminen |

Työntekijöiden terveys- ja turvallisuusmääräysten noudattaminen |

Vaarallisten päästöjen hallinta |

Palamisen ja räjähdyksen estäminen |

Hajunvalvontamääräykset |

Kestävät ympäristökäytännöt |

Päästöjen seuranta ja raportointi |

Jätehuoltomääräykset |

Energiatehokkuusohjeet |

Pölynhallinnan haasteet |

|---|

Suuri pölymäärä |

Terveysriskit |

Hajupäästöt |

Säännösten noudattaminen |

Palo- ja räjähdysvaarat |

Laitteiden kuluminen |

Vaarallisten jätteiden käsittely |

Ympäristövaikutus |

Ristikontaminaatio |

Tehokkaan pölynhallinnan keskeiset näkökohdat |

|---|

Edistykselliset pölynkeräysjärjestelmät |

Hajun ja VOC-yhdisteiden hallinta |

Lämpötilankestävä suodatus |

Bioaerosolisuodatus |

Reaaliaikainen päästöjen seuranta |

Vaarallisen pölyn eristäminen |

Säännöllinen huolto ja tarkastus |

Energiatehokkaat ratkaisut |

Mukautetut kasvien sopeutukset |

Ota yhteyttä asiantuntijakonsultaatioon

Tutustu muihin palveluihimme!

Usein kysytyt kysymykset

Ilman ja pölyn suodatus on välttämätöntä jätteenkäsittelyympäristöissä haitallisten hiukkasten, kaasujen ja hajujen talteen ottamiseksi, joita vapautuu jätteen käsittelyn, polttamisen tai prosessoinnin aikana. Nämä epäpuhtaudet voivat aiheuttaa vakavia terveys- ja ympäristöriskejä, jos niitä ei käsitellä. Tehokkaat suodatusjärjestelmät varmistavat määräysten noudattamisen, suojaavat työntekijöiden turvallisuutta ja edistävät puhtaampaa toimintaa.

Jätetyypin ja käsittelyprosessin mukaan käytetään erilaisia suodatusjärjestelmiä. Yleisiä ratkaisuja ovat pussisuodattimet hienojen hiukkasten talteenottoon, märkäpesurit happamien kaasujen ja liukoisten yhdisteiden poistamiseen sekä aktiivihiilijärjestelmät hajunpoistoon. Syklonierottimia käytetään usein suurempien hiukkasten käsittelyyn ennen hienosuodatusta. Ilma-ilma-lämmönvaihtimia voidaan käyttää myös energian talteenottoon jätteenpolttolaitoksissa.

Suodatusjärjestelmät auttavat vähentämään pölyn, myrkyllisten kaasujen ja haihtuvien yhdisteiden päästöjä, jolloin laitokset voivat täyttää paikalliset ja kansainväliset ympäristöstandardit. Niillä on tärkeä rooli päästöjen pitämisessä sallittujen rajojen alapuolella, ja ne ovat välttämättömiä ympäristölupien saamiseksi ja yleisön luottamuksen ylläpitämiseksi.