What Is a Dust Collector Explosion?

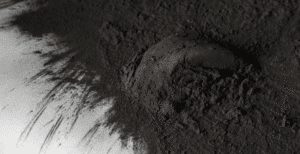

A dust collector explosion is a sudden and powerful blast that happens in a dust collection system. This type of explosion happens when certain conditions come together. These conditions include the presence of combustible dust, enough oxygen, and an ignition source.

- Combustible Dust: This is fine dust that can ignite and cause an explosion. Many materials like wood, metal, and food can create combustible dust.

- Oxygen: Dust needs oxygen to burn. If there is enough oxygen in the air, it can help the dust ignite.

- Ignition Sources: These are things that can spark a fire. Common sources include sparks from machinery, hot surfaces, or static electricity.

When all three elements are present, a dust collector explosion can occur. It can be very dangerous and cause serious damage. Understanding these components helps people take precautions to avoid such incidents.

Causes of Dust Collector Explosions

Dust collector explosions can happen for several reasons. Understanding these causes can help prevent accidents.

One common cause is electrostatic discharge. This occurs when static electricity builds up in the dust collector and suddenly releases. This release can cause a big explosion if the dust is flammable.

Another cause is sparks from upstream processes. If machines or tools create sparks, these can ignite dust in the collector. This situation is dangerous, especially if the dust is dry and flammable. Smoldering dust accumulation is also a problem. Sometimes, dust can build up and start to smolder. If it gets hot enough, it can cause an explosion. Keeping dust levels low is important to prevent this.

By knowing these causes, people can take steps to keep dust collectors safe.

Importance of Dust Ventilation Systems

Dust ventilation systems play a key role in preventing explosions. They help remove dust from the air and keep work areas safe. When dust builds up, it can create a fire hazard. A dust explosion can cause serious damage and injury. Proper ventilation prevents this by reducing dust accumulation.

Dust ventilation systems work by moving air in and out of a space. This keeps dust levels low. When there is good airflow, dust does not settle on surfaces. Less dust means a lower risk of explosion.

Here are some important points about dust ventilation systems:

- Prevent Accumulation: They help stop dust from building up in one place.

- Improve Safety: By keeping dust levels low, they make work areas safer for everyone.

- Protect Equipment: Less dust means less wear and tear on machines.

- Maintain Air Quality: Good ventilation improves the air that workers breathe.

Overall, dust ventilation systems are essential for safe working conditions. They help avoid dangerous situations and keep operations running smoothly.

Preventive Measures and Best Practices

Preventive measures and best practices are very important to stop dust collector explosions. These steps help keep workers safe and protect equipment. Here are some strategies to follow:

- Säännöllinen huolto: Check dust collectors often. Clean filters and remove dust buildup. This keeps machines working well and reduces explosion risks.

- Proper Housekeeping: Keep the area clean. Remove dust from floors and surfaces. Use wet cleaning methods when possible. This lowers dust levels in the air.

- Use Explosion Protection Devices: Install devices that can stop explosions. These include explosion vents and suppression systems. They help control pressure and fire.

- Train Workers: Teach workers about dust hazards. Make sure they know how to spot problems. Training helps them act safely in risky situations.

- Monitor Dust Levels: Use sensors to track dust levels. If levels get too high, take action. This can prevent dangerous situations before they happen.

Following these steps can greatly reduce the chances of dust collector explosions. Safety is a shared responsibility, and everyone plays a role.

Sääntelystandardit ja vaatimustenmukaisuus

Regulatory standards and compliance are important for filtration systems in industrial settings. OSHA and NFPA set rules that companies must follow to ensure safety and health.

Here are some key points about these regulations:

- OSHA stands for the Occupational Safety and Health Administration. It creates rules to protect workers from harmful conditions.

- OSHA requires companies to use filtration systems to reduce harmful air pollutants.

- NFPA stands for the National Fire Protection Association. It sets standards for fire safety in buildings.

- NFPA has guidelines for using filtration systems to prevent fires and explosions in industrial areas.

- Both OSHA and NFPA require regular checks and maintenance of filtration systems to ensure they work properly.

- Companies must train workers on how to use and maintain these systems safely.

- Following these regulations helps create a safer work environment for everyone.

Understanding these standards helps companies stay compliant and protect their workers.

Case Studies and Real-World Examples

Case studies of dust collector explosions show how serious these events can be. These examples help people understand what went wrong and how to prevent future accidents. The key to safety is to follow strict safety protocols.

One example is the explosion in a food processing plant. Dust from flour built up in a dust collector. A spark ignited the dust, causing a huge explosion. This event injured several workers and caused major damage. The lesson learned was to regularly clean the dust collector and check for sparks.

Another case happened in a woodworking shop. Sawdust accumulated in the dust collector. When the dust became too thick, a small flame caused an explosion. This accident showed the need for proper ventilation and regular maintenance of dust collectors.

Key points from these examples include:

- Regular Cleaning: Always clean dust collectors to reduce buildup.

- Check for Sparks: Look for sparks or flames near dust collectors.

- Proper Ventilation: Ensure good airflow to prevent dust from accumulating.

- Safety Training: Train workers on safety protocols and emergency procedures.

These case studies highlight the importance of safety in industries that use dust collectors. Following safety protocols can save lives and prevent damage to property.

Johtopäätös

Dust collector explosions can be very dangerous. It is important to understand how they happen and what can be done to prevent them. Knowing the causes helps workers stay safe. Preventive measures, like regular maintenance and proper design, can reduce the risk of these explosions. Workers should always be aware of their surroundings and follow safety rules.

Keeping a safe working environment is everyone’s responsibility. By understanding dust collector explosions and taking the right steps, workers can help protect themselves and their coworkers. Safety should always come first in the workplace.