Industrial emission norms across cement, steel, power, and process industries have tightened across the world. Plants are expected to maintain emissions below 10 mg/Nm³ consistently, not just during controlled tests but during everyday operation. Achieving this level of compliance while protecting production hours, avoiding baghouse shutdowns, and keeping operating costs stable has become a top priority for engineering and environmental teams.

PTFE membrane filter bags have emerged as the most reliable filtration technology for plants targeting sub-10 mg/Nm³ emissions. Their ability to combine ultra-low emissions with stable pressure drop and long service life has shifted them from a specialty product to an industry standard. This article explains how PTFE membrane bags deliver these results, what improvements plants see after upgrading, and how Intensiv Filter Himenviro supports long-term performance.

1. What Makes PTFE Membrane Bags a Superior Solution

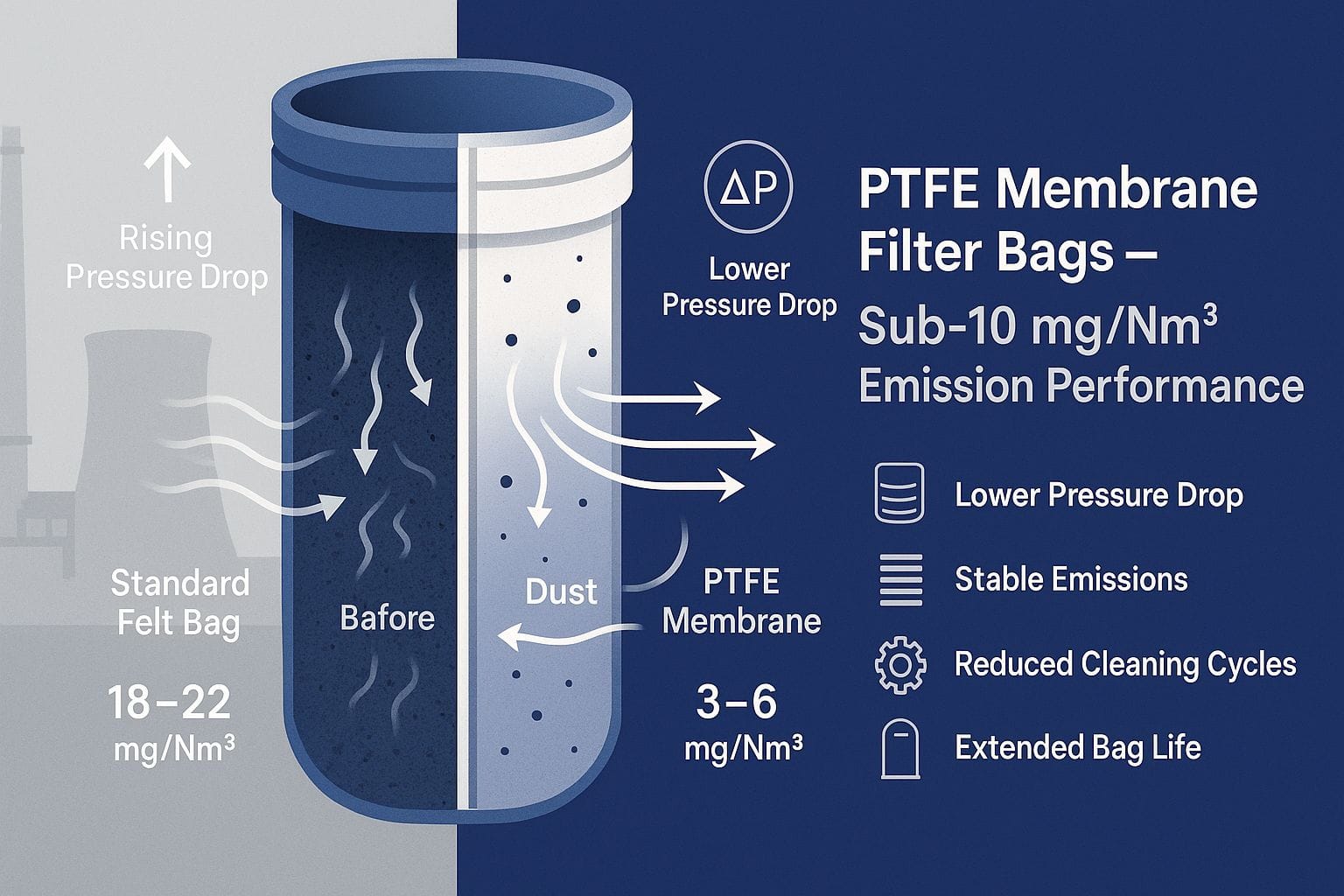

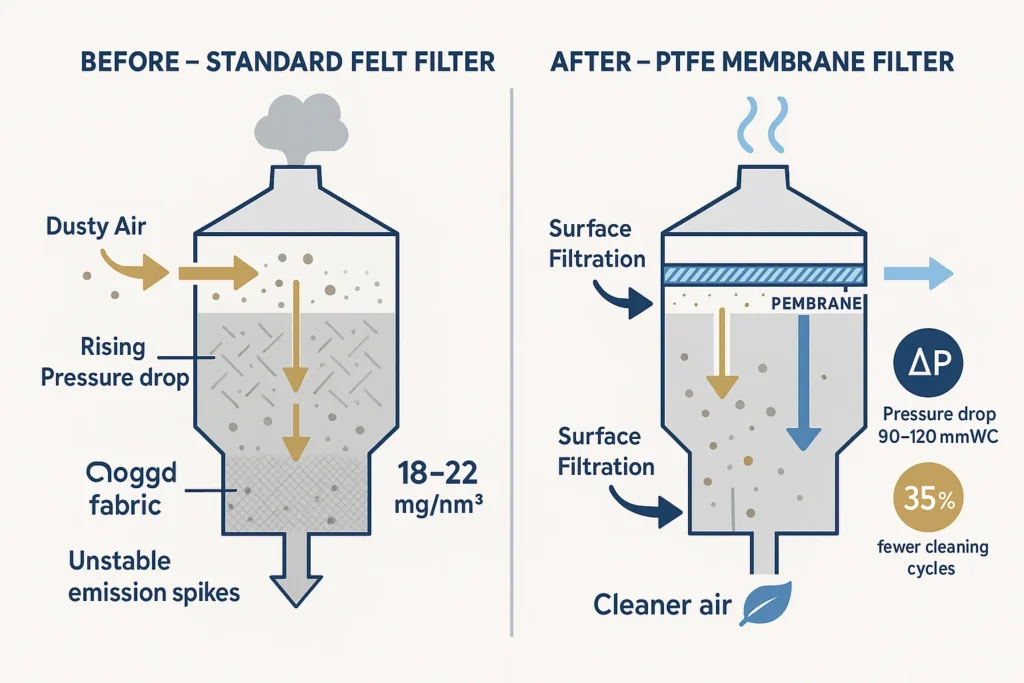

Conventional needle-felt bags work on depth filtration. Dust penetrates deep into the fabric, gradually clogs the felt, and forces the cleaning system to work harder over time. This leads to early pressure drop increase, unstable emissions, and accelerated bag wear.

PTFE membrane bags function differently. A microporous PTFE membrane is bonded to the base fabric, creating a smooth surface that traps particles externally. Dust remains on the surface rather than embedding inside the felt. This design ensures cleaner pulses, consistent airflow, and the ability to capture sub-micron particles from the very first hour of operation.

Plants upgrading to PTFE membranes consistently report emissions in the range of 3 to 6 mg/Nm³, offering a comfortable margin below the 10 mg/Nm³ requirement.

Ensure Clean Air and Regulatory Compliance Today

2. How PTFE Membrane Technology Achieves Sub-10 mg/Nm³ Performance

The pore structure of PTFE membranes is highly uniform. This allows fine particulate capture without restricting airflow. The result is a stable dust cake that forms and releases cleanly during pulsing, ensuring predictable operation throughout the bag’s lifecycle.

This stability is essential in plants where process conditions fluctuate. Kiln transitions, fuel changes, high-moisture periods, or boiler load variations often cause emission spikes with standard bags. PTFE membranes handle these fluctuations far better, maintaining low emissions even during upset conditions.

3. The Advantage of Lower Pressure Drop

A notable operational benefit of PTFE membrane bags is the reduction and stabilization of differential pressure. While felt bags typically start with a pressure drop between 150 and 170 mmWC, PTFE membranes often begin around 90 to 110 mmWC. More importantly, they maintain this range for a significantly longer period.

Stable pressure drop provides several advantages:

- Reduced ID fan load

- Lower electricity consumption

- Smoother airflow through the baghouse

- Fewer and gentler pulse jet cycles

- Lower wear on bag fabric and mechanical parts

Because dust does not penetrate the felt, PTFE bags exhibit a slower rate of ΔP increase, allowing the cleaning system to operate under far less stress.

4. Realistic Before and After Performance Comparison

Below is a practical comparison based on performance improvements observed in cement plants, steel dedusting systems, and WHR boilers after transitioning to PTFE membrane bags.

| Parametri | Before – Standard Felt | After – PTFE Membrane |

|---|---|---|

| Emission Range | 18 to 22 mg/Nm³ | 3 to 6 mg/Nm³, consistently below 10 mg/Nm³ |

| Differential Pressure | Rapid increase, unstable | Stable between 90 and 120 mmWC |

| Cleaning Frequency | High due to dust penetration | Up to 35% reduced |

| Bag Life | 1.5 to 2 years | 2.5 to 4 years |

| Compressed Air Use | Elevated | Noticeably lower |

| Seisokki | More frequent | Predictable and reduced |

Plants clearly experience more stable baghouse performance and reduced operational risks after switching to PTFE membranes.

5. Applications Where PTFE Provides Maximum Impact

PTFE membrane bags perform especially well in demanding environments, including:

- High temperature processes

- Dust with acidic or corrosive characteristics

- Moisture-sensitive operations

- Processes generating sticky or ultra-fine dust

Industries such as cement, steel, power generation, chemicals, and carbon black benefit significantly from this technology. PTFE membranes prevent fabric blinding, maintain permeability, and resist chemical degradation that typically shortens the life of standard bags.

6. Reduction in Maintenance and Unplanned Downtime

Maintenance teams immediately notice the difference after installing PTFE bags. The smooth PTFE surface does not allow dust to embed, which means pulsing is more effective and uniform. This improves predictability, minimizes hot-spot failures, and reduces the need for emergency shutdowns.

Plants experience fewer pressure drop alarms, more consistent airflow, and a noticeable decline in bag replacement frequency. In continuous-process industries where every shutdown impacts productivity, this reliability becomes a major advantage.

7. Why PTFE Membranes Make Financial Sense

Although PTFE membrane bags require a higher initial investment, the lifecycle benefits outweigh the cost. Plants recover their investment through:

- Lower ID fan energy

- Reduced compressed air usage

- Fewer bag changes

- Less labor and maintenance involvement

- Stable emissions that prevent penalties

The upgrade often pays for itself through operational savings and improved production continuity.

8. Key Considerations When Selecting PTFE Membrane Bags

Not all PTFE membrane bags are equal. To ensure consistent performance, plants should evaluate factors such as membrane uniformity, lamination quality, seam sealing, substrate compatibility, and the precision of manufacturing. The right combination ensures filtration efficiency remains intact throughout the service life of the bag.

A well-engineered PTFE bag maintains low emissions and stable ΔP across a wide range of temperatures and dust conditions.

Tutustu ratkaisuvalikoimaamme:

Why Intensiv Filter Himenviro is a Trusted Partner for PTFE Membrane Solutions

With more than a century of filtration engineering experience, Intensiv Filter Himenviro brings deep expertise to the design and manufacturing of PTFE membrane filter bags. Our membranes are designed for accuracy, durability, and thermal stability. Every bag undergoes careful quality checks to ensure uniform performance and long-term reliability in demanding industrial environments.

Along with product expertise, we offer baghouse performance diagnostics, operational optimization support, and technical audits to help plants maximize the value of their filtration system.

Johtopäätös

PTFE membrane filter bags have become the most dependable solution for achieving consistent sub-10 mg/Nm³ emissions. Their ability to maintain low pressure drop, remain cleanable, and deliver extended service life makes them the preferred choice for compliance-driven operations. Plants that upgrade to PTFE membranes experience better stability, fewer disruptions, and measurable reductions in operating costs.

If your plant is facing rising ΔP, unstable emissions, or repeated shutdowns, PTFE membrane bags can transform your filtration performance.

Get a free technical evaluation from Intensiv Filter Himenviro and discover how PTFE membrane bags can help your plant achieve stable, reliable, and compliant sub-10 mg/Nm³ emissions.

Request a baghouse performance assessment today.

Usein kysytyt kysymykset

PTFE filter cloth is a high-performance filtration fabric made from Polytetrafluoroethylene. It is engineered for industrial baghouses where temperature, chemical exposure, and fine particulate loads are high. Unlike standard needle-felt fabrics, PTFE filter cloth offers exceptional chemical inertness, hydrophobicity, and thermal stability. This makes it ideal for applications where consistent low emissions, long service life, and resistance to moisture or acidic gases are required.

PTFE filter cloth is commonly used as the base substrate for PTFE membrane filter bags, delivering superior dust release and extremely low particle penetration.

PTFE filters are used in industries where achieving ultra-low emissions and stable pressure drop is critical. They are specifically designed for harsh environments involving corrosive gases, high temperatures, sticky dust, or extremely fine particulate.

Typical uses include cement kilns, steel furnace dedusting systems, WHR boilers, carbon black processing, chemical reactors, and high-moisture processes. PTFE filters ensure stable baghouse performance, reduced downtime, longer bag life, and compliance with strict emission norms below 10 mg/Nm³.

A PTFE filter is a dust filtration media that uses a microporous PTFE surface to trap fine particles at the surface level instead of letting them penetrate the fabric. This mechanism, known as surface filtration, ensures that dust forms a thin, easily cleanable layer on the membrane.

The result is consistently low emissions, slower rise in differential pressure, cleaner pulse cycles, and a significantly longer service life compared to standard needle-felt bags. PTFE filters function reliably even during process upsets, high moisture conditions, or sudden dust surges.

PTFE membrane filter bags are high-efficiency industrial dust collector bags made by laminating a microporous PTFE membrane onto a filter cloth substrate. These bags capture sub-micron particles on the surface, enabling industries to consistently achieve emission levels below 10 mg/Nm³.

They offer several performance advantages, including low initial pressure drop, reduced pulse jet frequency, longer operational life, and superior resistance to acids, alkalis, and moisture. PTFE membrane bags are the preferred choice for compliance-driven plants aiming for reliable and continuous operation.