Every industry, from manufacturing plants to power generation facilities, relies on machinery and processes that generate substantial heat. Left unchecked, this heat can lead to decreased efficiency, equipment failure, and even dangerous working conditions. That’s where Industrial Cooling Solutions come into play, acting as the unsung heroes that keep operations running smoothly and safely.

But what exactly are industrial cooling solutions, and why are they so vital? Let’s delve into the world of temperature management and understand the importance of effective cooling strategies within the industrial landscape.

Beyond Comfort: The Critical Role of Cooling

While keeping employees comfortable is certainly a benefit of industrial cooling, its impact extends far beyond mere convenience. Heat can wreak havoc on sensitive equipment, causing everything from degraded performance to complete breakdowns. For instance, overheating machines are prone to requiring frequent repairs, leading to costly downtime and lost productivity. Precise temperature control is often essential for maintaining the integrity of finished products. In the food and beverage industry, for example, accurate cooling is crucial for preventing spoilage and ensuring product safety.

Furthermore, uncontrolled heat can pose significant safety risks. Overheated machinery can become a fire hazard, and excessive temperatures can contribute to heatstroke and other heat-related illnesses among workers. Implementing effective Industrial Cooling Solutions is a proactive measure that protects both valuable assets and the well-being of your workforce.

Understanding the Landscape of Cooling Technologies

The world of industrial cooling offers a diverse range of technologies, each suited to different applications and requirements. Choosing the right solution depends on factors such as the size of the space, the amount of heat generated, and the specific industry involved. Some common examples include:

- Air-Cooled Chillers: These systems use air to cool a refrigerant, which then chills water or other fluids circulated to cool equipment or spaces. They are relatively easy to install and maintain, making them a popular choice for various applications.

- Water-Cooled Chillers: These chillers utilize water to dissipate heat, offering higher efficiency compared to air-cooled systems. They are often preferred for larger facilities with significant cooling demands.

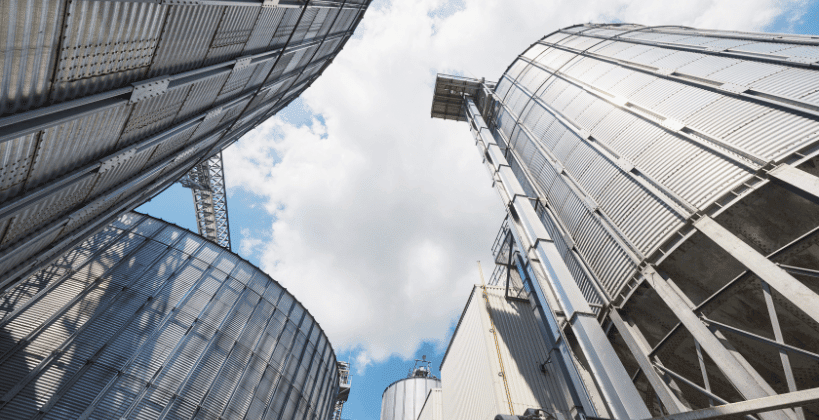

- Cooling Towers: These structures are designed to cool water by evaporating a portion of it, releasing heat into the atmosphere. They are commonly used in power plants, refineries, and large industrial facilities where large volumes of cooling water are required.

- Evaporative Coolers: These systems use the evaporation of water to cool air, offering an energy-efficient solution for certain climates and applications. They are particularly effective in dry environments where the humidity is low.

- Direct and Indirect Cooling Systems: These systems focus on directly cooling equipment or machinery with targeted methods. They are useful in the food industries and more.

Descubra nuestra gama de soluciones:

Investing in the Future: The Benefits of Proactive Cooling

Implementing an effective Industrial Cooling Solutions system is not just an expense; it’s an investment in the longevity and efficiency of your operations. By proactively managing heat, you can expect to see a range of benefits, including:

- Increased Equipment Lifespan: Consistent temperatures reduce wear and tear on machinery, extending its operational life and reducing the need for costly replacements.

- Eficiencia energética mejorada: Optimized cooling systems can significantly reduce energy consumption, lowering operating costs and minimizing your environmental footprint.

- Tiempo de inactividad reducido: Preventing overheating and equipment failure translates to less unscheduled downtime, ensuring consistent production and minimizing lost revenue.

- Enhanced Worker Safety: A comfortable and safe working environment improves morale, reduces the risk of heat-related illnesses, and enhances overall productivity.

- Streamlined Processing: Improve product integrity and production speed with better and more accurate temperature control.

Choosing the Right Partner for Your Cooling Needs

Navigating the complexities of industrial cooling requires expertise and experience. Partnering with a reputable provider like Intensiv Filter Himenviro ensures that you receive tailored solutions that meet your specific requirements. We offer a comprehensive range of services, from system design and installation to ongoing maintenance and support. Our team of experts can help you assess your cooling needs, recommend the most appropriate technologies, and implement a strategy that maximizes efficiency, reduces costs, and ensures the long-term reliability of your operations.

Don’t let heat compromise the performance and safety of your industrial facility. Invest in Industrial Cooling Solutions and experience the benefits of efficient temperature management. Contact Intensiv Filter Himenviro today to explore your options and discover how we can help you beat the heat and optimize your operations.