Oficinas

SEDE CENTRAL

Alemania

- Filtro intensivo Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Alemania - +49 20534200990

OFICINA REGIONAL

Gran Bretaña

- Filtro intensivo Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Gran Bretaña - +44 1922 628893

OFICINA REGIONAL

Emiratos Árabes Unidos

- Filtro intensivo Himenviro Technologies FZE – LLC

Centro de negocios, Zona franca de Sharjah Publishing City, Sharjah, Emiratos Árabes Unidos - +971-556074697

OFICINA REGIONAL

India

- Filtro intensivo Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

OFICINA REGIONAL

India

- Filtro intensivo Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

OFICINA REGIONAL

India

- Filtro intensivo Himenviro Private Limited

D-247/11, Sector-63, Noida - 201301, Uttar Pradesh, India - +91-120-4642-500

Soluciones de filtración de aire y polvo para la industria alimentaria

La industria de alimentos y bebidas Es un sector complejo y altamente regulado que depende de procesos precisos y estrictos estándares de higiene. Un aspecto crucial para mantener estos estándares es el control eficaz del polvo. Procesos como la manipulación, mezcla y envasado de granos generan partículas finas de polvo que pueden contaminar los productos, representar riesgos para la salud de los trabajadores y crear posibles riesgos de explosión.

Para abordar estos desafíos, ofrecemos soluciones avanzadas soluciones de filtración Diseñados específicamente para la industria de alimentos y bebidas, nuestros sistemas están diseñados para capturar y eliminar partículas de polvo, garantizando la pureza del producto, la seguridad de los trabajadores y el cumplimiento normativo.

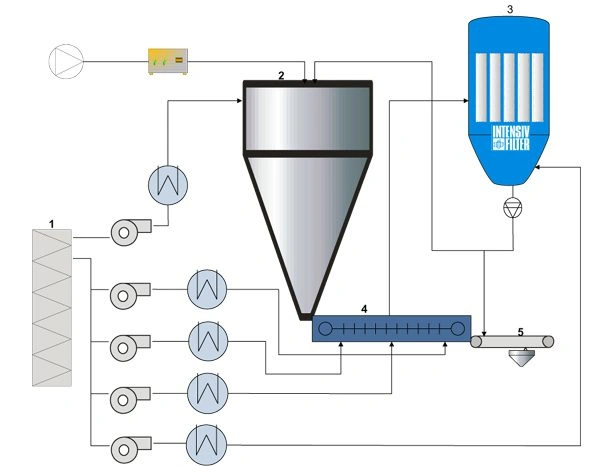

Proceso de filtración de polvo en la industria alimentaria

- 1. Filtro exterior

- 2. Secador por aspersión

- 3. Filtro CIP

- 4. Lecho fluidizado externo

- 5. Relleno

Especificación requerida para el filtro CIP

Datos de diseño típicos | Filtro CIP |

|---|---|

Volumen de gas | < 230.000 m³/h |

Temperatura del gas | 80-90 °C |

Tipo de polvo | Productos lácteos en polvo |

Contenido de polvo residual | < 10 g/m³ |

Contenido de polvo de gas crudo | 20 mg/m³ |

Limpieza | En línea |

Medio filtrante | Poliéster |

Diseño a prueba de explosiones | Sí |

Absorbente |

Aplicación de nuestros productos para la industria alimentaria

Captura el polvo generado durante la transferencia de materiales a granel, como granos, polvos y copos.

Controlar las emisiones de polvo de procesos de alta energía como molienda, trituración y pulverización.

Panorama regulatorio para el control del polvo |

|---|

Reglamento de seguridad alimentaria |

Cumplimiento de las normas de la FDA y el USDA |

Salud y seguridad del trabajador |

Cumplimiento de las regulaciones de OSHA |

Prevención de incendios y explosiones |

Implementación de las normas NFPA |

Protección ambiental |

Calidad y consistencia del producto |

Reducción del tiempo de inactividad y de los costes de mantenimiento |

Desafíos del control del polvo |

|---|

Contaminación del producto |

Riesgos para la salud de los trabajadores |

Peligros de incendio y explosión |

Cumplimiento normativo |

Contaminación cruzada |

Crecimiento microbiano |

Adherencia a estrictas normas de seguridad alimentaria |

Calidad reducida del producto |

Daños al equipo |

Consideraciones clave para un control eficaz del polvo |

|---|

Implementar una captura de polvo eficaz |

Asegúrese de que haya un flujo de aire y una presión adecuados |

Productos lácteos en polvo |

Utilice sistemas de filtración de alta eficiencia |

Mantenimiento e inspección regulares |

Cumplir con los estándares de la industria |

Evaluar periódicamente el sistema de control de polvo |

Consideraciones específicas del proceso |

Evaluación y mitigación de riesgos |

Conéctese con nosotros para una consulta con expertos

¡Explora nuestros otros servicios!

Preguntas frecuentes

En el procesamiento de alimentos, los sistemas de filtración comunes incluyen filtros de membrana (como microfiltración, ultrafiltración, nanofiltración y ósmosis inversa), filtros de profundidad, filtros de carbón activado y sistemas de luz ultravioleta (UV). Estas tecnologías se emplean para eliminar contaminantes físicos, químicos y biológicos, garantizando así la pureza y seguridad del producto.

Los sistemas de filtración garantizan el cumplimiento de las normas de seguridad alimentaria mediante la eliminación eficaz de contaminantes, como microorganismos, partículas y residuos químicos, de las materias primas y los productos. Este proceso de purificación contribuye al cumplimiento de los requisitos normativos y mantiene altos estándares de calidad en los productos alimenticios finales.

Los sistemas de filtración mantienen la calidad y consistencia del producto eliminando partículas indeseadas, microorganismos y otros contaminantes de los ingredientes y productos finales. Esto garantiza que cada lote cumpla con los estándares de pureza y calidad deseados, lo que se traduce en uniformidad en sabor, apariencia y seguridad en todos los productos.