Dust Removal

In many industrial processes, air serves as the working medium and is thereby altered in composition or impurities increase to such during pneumatic conveying bulk materials.

Many specks of dust are harmful, toxic or explosive and damage people and the environment. If the air can be conducted later from the process back in the atmosphere, the contaminants must be removed. Another gas, for example, nitrogen, is often used as a working medium. Even then, the pollutants must be filtered either to return the cleaned gas in the process or to recover valuable products back.

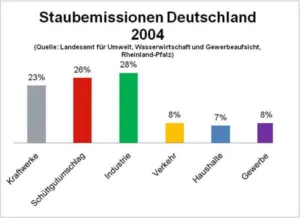

Dust emissions in Germany

Through the use of the Dedusting system in the industry and in the energy sector could Grit dust content in weight be suppressed considerably since the 80s?

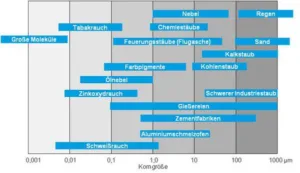

Industrial dust

The dust particles contained in the dust-containing gas streams can have usually a particle size range from 0.1 to 1,000 microns.

Technical methods for dedusting

Dust particles and gas are separated using different dedusting processes and dust separators:

- Gravity separator (e.g. settling chamber)

- Centrifugal force separator (e.g. cyclone)

- Wet separators (rotary scrubbers, high-performance scrubbers, etc.)

- Electrical separators (electrostatic filters)

- Filtration separator (fabric filter, cartridge filter)

Separation degrees of different dust separators. The degree of separation always depends on the particle size.

- Separation degrees of different dust separators. The degree of separation always depends on the particle size. Source: Bank, Matthias Dr., Basic Knowledge of Environmental Technology, 2006

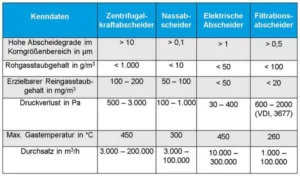

Comparison of different dust collectors