In industrial environments where airborne particles, dust, and contaminants are a daily reality, clean air isn’t just a matter of comfort—it’s a necessity. While terms like dust collection and air filtration are often used interchangeably, they refer to two distinct processes that serve different purposes in maintaining air quality and equipment integrity. Understanding the difference between them is crucial for selecting the right solution for your facility’s operational and environmental needs.

At Intensiv Filter Himenviro, we specialize in delivering both dust collection and air filtration systems for a variety of industries—from cement and power to pharmaceuticals and food processing. This article breaks down the fundamentals of each process, their applications, key differences, and how to choose the best system for your specific challenges.

What Is Dust Collection?

Dust collection is a process designed to capture and remove larger particulate matter directly from the source of generation before it can disperse into the workspace or the environment. These particles can be visible dust, powder, or other solid pollutants emitted during industrial processes such as grinding, cutting, mixing, conveying, or loading/unloading of materials.

A typical dust collection system includes:

-

Hoods or capture devices at the source of dust

-

Rohrleitungen for transporting the contaminated air

-

Dust collectors such as baghouses, cyclones, or electrostatic precipitators (ESPs)

-

Lüfter und Gebläse for airflow control

-

Dust storage or disposal units

Dust collection systems are designed to remove airborne solids, not gases or vapors, and are usually implemented for:

-

Product recovery (e.g., collecting valuable dust in chemical or food plants)

-

Employee protection (avoiding respiratory hazards)

-

Equipment protection (preventing dust buildup on sensitive components)

-

Environmental compliance

Entdecken Sie unser Lösungsangebot:

What Is Air Filtration?

On the other hand, air filtration refers to the process of cleaning the air from finer particles, aerosols, and even microbial contaminants after it has been dispersed into the ambient air or within a closed environment. Air filtration systems are typically concerned with improving indoor air quality and are found not just in industrial settings, but also in commercial buildings, laboratories, and cleanrooms.

Air filtration systems use:

High-efficiency filters (like HEPA, ULPA, or activated carbon filters)

Pre-filters to trap larger particles before they reach the main filters

Recirculating or exhaust fans

Monitoring units for filter performance and air quality

These systems are designed to deal with smaller particulates that remain airborne, including:

Feinstaub

Pollen

Smoke

Pathogens and allergens

Chemical fumes

Unlike dust collection, air filtration often targets indoor environments or end-of-pipe emissions, where the air has already dispersed and needs to be purified before further circulation or release.

Kontaktieren Sie uns jetzt

Key Differences Between Dust Collection and Air Filtration

Understanding how the two systems differ can help you better design your pollution control strategy. Here’s a comparison across critical parameters:

|

Parameter

|

Staubsammlung

|

Air Filtration

|

|---|---|---|

|

Zweck

|

Remove dust at the source

|

Clean ambient or processed air

|

|

Partikelgröße

|

Targets large to medium particles

|

Targets fine particles, fumes and aerosols

|

|

Application Stage

|

Pre-ventilation/at source

|

Post-ventilation or indoor environment

|

|

Systemtyp

|

Baghouses, cyclones, ESPs

|

HEPA filters, carbon filters, HVAC filters

|

|

Industrial Use

|

Heavy-duty processes

|

Cleanroom, labs, HVAC systems

|

|

End Goal

|

Material recovery, emission control

|

Air quality improvement, odor/gas removal

|

When to Use Dust Collection vs. Air Filtration

Choosing between a dust collection system and an air filtration system depends entirely on the nature of your operations:

Use Dust Collection when:

You deal with bulk material handling that generates significant dust.

Your operation involves process-generated dust that is best controlled at the source.

You want to recover valuable materials like metal powders, chemicals, or food ingredients.

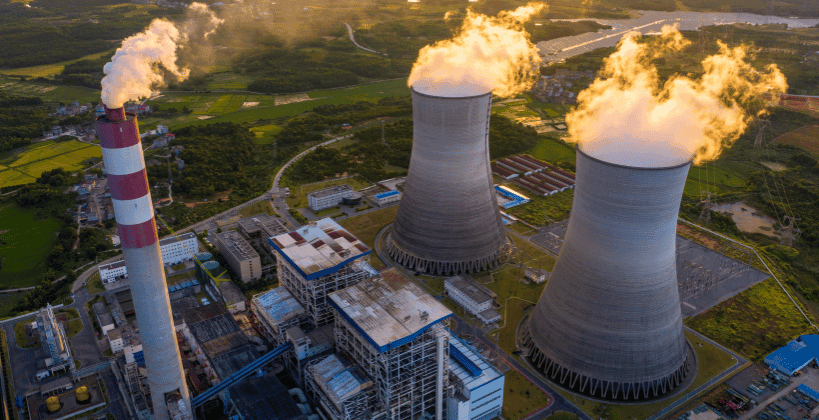

Your industry is subject to strict particulate emission norms (e.g., cement, metallurgy, power generation).

Use Air Filtration when:

Your concern is ambient air quality for workers and sensitive environments.

You operate in a cleanroom, pharmaceutical plant, or electronics assembly area.

The emissions contain fine particles, pathogens, or fumes that escape collection hoods.

You’re looking to supplement your dust collection system to improve overall air purity.

Often, the most effective strategy involves a hybrid approach, using dust collection at the source and air filtration for residual control, ensuring both worker safety and regulatory compliance.

How Intensiv Filter Himenviro Delivers Both

At Intensiv Filter Himenviro, we offer a complete range of engineered solutions for dust collection and air filtration, customized to meet your process, space, and environmental demands.

Our Dust Collection Solutions:

Rückwärts-Airbag-Gehäuse

Pulse Jet Filters

Elektrostatische Abscheider (ESPs)

Zyklone und Multiklone

Our Air Filtration Capabilities:

Modular air filtration units

HEPA and ULPA-based filtration systems

Cleanroom air management systems

Gas-phase filtration units (for chemical fumes and odors)

By conducting on-site assessments, dust analysis, Und air quality measurements, we recommend the most effective and efficient systems—either individually or as integrated units—for long-term reliability and compliance.

Final Thoughts

While dust collection and air filtration may appear to serve the same general goal—removing contaminants from the air—their applications, mechanisms, and impact are distinctly different. Understanding these differences is critical when designing pollution control strategies that not only comply with environmental standards but also protect human health, maintain process efficiency, and reduce operational downtime.

Whether you need a robust dust collection system for your cement plant or a high-performance air filtration unit for a pharmaceutical cleanroom, the key lies in choosing the right solution for the right problem—and that’s exactly what Intensiv Filter Himenviro is here to deliver.