Офиси

СЕДАЛИЩЕ

Германия

- Интензивен филтър Himenviro Technologies GmbH

Neustraße 45 - 49, 42553, Velbert, Deutschland/Германия - +49 20534200990

РЕГИОНАЛЕН ОФИС

Великобритания

- Интензивен филтър Himenviro UK Limited

47, Bath Street WS13BX, Wallsall West Midlands, Великобритания - +44 1922 628893

РЕГИОНАЛЕН ОФИС

Обединени арабски емирства

- Интензивен филтър Himenviro Technologies FZE – LLC

Бизнес център, Sharjah Publishing City Free Zone, Sharjah, ОАЕ - +971-556074697

РЕГИОНАЛЕН ОФИС

Индия

- Интензивен филтър Himenviro Private Limited

D-247/11, сектор-63, Noida - 201301, Утар Прадеш, Индия - +91-120-4642-500

РЕГИОНАЛЕН ОФИС

Индия

- Интензивен филтър Himenviro Private Limited

D-247/11, сектор-63, Noida - 201301, Утар Прадеш, Индия - +91-120-4642-500

РЕГИОНАЛЕН ОФИС

Индия

- Интензивен филтър Himenviro Private Limited

D-247/11, сектор-63, Noida - 201301, Утар Прадеш, Индия - +91-120-4642-500

Решения за филтриране на въздух и прах в хранително-вкусовата промишленост

Хранително-вкусовата промишленост е сложен и силно регулиран сектор, който разчита на прецизни процеси и строги хигиенни стандарти. Един от критичните аспекти на поддържането на тези стандарти е ефективният контрол на праха. Процеси като обработка на зърно, смесване, блендиране и опаковане генерират фини прахови частици, които могат да замърсят продуктите, да представляват риск за здравето на работниците и да създадат потенциални опасности от експлозия.

За да се справим с тези предизвикателства, ние предлагаме усъвършенствани филтрационни решения специално проектирани за хранително-вкусовата промишленост. Нашите системи са проектирани да улавят и отстраняват прахови частици, осигурявайки чистота на продукта, безопасност на работниците и съответствие с нормативните изисквания.

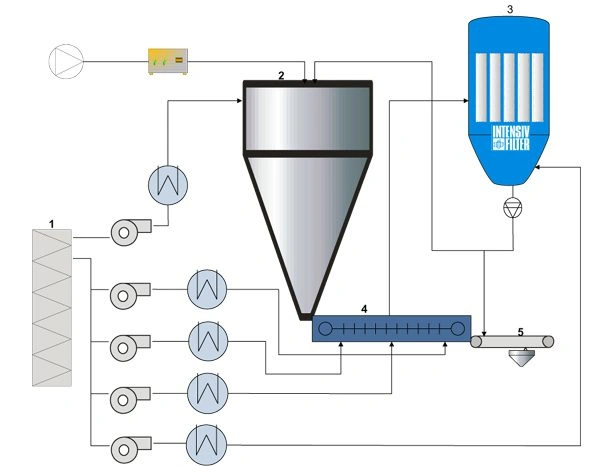

Процес на филтриране на прах в хранително-вкусовата промишленост

- 1. Външен филтър

- 2. Спрей сушилня

- 3. CIP филтър

- 4. Външен кипящ слой

- 5. Пълнеж

Необходима спецификация за CIP филтъра

Типични проектни данни | CIP филтър |

|---|---|

Обем на газа | < 230 000 м³/ч |

Температура на газа | 80-90°C |

Вид прах | Сухи млечни продукти |

Съдържание на остатъчен прах | < 10 г/м³ |

Съдържание на прах от необработен газ | 20 мг/м³ |

Почистване | Он-лайн |

Филтърна среда | Полиестер |

Дизайн с класификация на експлозия | да |

Сорбент |

Приложение на нашите продукти за хранително-вкусовата промишленост

Улавяне на прах, генериран по време на прехвърлянето на насипни материали, като зърна, прахове и люспи.

Контролирайте емисиите на прах от високоенергийни процеси като смилане, шлифоване и пулверизиране.

Регулаторен пейзаж за контрол на праха |

|---|

Правилник за безопасност на храните |

Спазване на стандартите на FDA и USDA |

Здраве и безопасност на работниците |

Съответствие с разпоредбите на OSHA |

Предотвратяване на пожари и експлозии |

Прилагане на стандартите на NFPA |

Опазване на околната среда |

Качество и постоянство на продукта |

Намалени разходи за престой и поддръжка |

Предизвикателства при контрола на праха |

|---|

Замърсяване на продукта |

Рискове за здравето на работниците |

Опасности от пожар и експлозия |

Съответствие с нормативната уредба |

Кръстосано замърсяване |

Микробен растеж |

Спазване на строги правила за безопасност на храните |

Намалено качество на продукта |

Повреда на оборудването |

Ключови съображения за ефективен контрол на праха |

|---|

Приложете ефективно улавяне на прах |

Осигурете правилен въздушен поток и налягане |

Сухи млечни продукти |

Използвайте високоефективни филтриращи системи |

Редовна поддръжка и инспекция |

Спазвайте индустриалните стандарти |

Редовно оценявайте системата за контрол на праха |

Специфични за процеса съображения |

Оценка и смекчаване на риска |

Свържете се с нас за експертна консултация

Разгледайте другите ни услуги!

Често задавани въпроси

В хранително-вкусовата промишленост, често срещаните филтрационни системи включват мембранни филтри (като микрофилтрация, ултрафилтрация, нанофилтрация и обратна осмоза), дълбочинни филтри, филтри с активен въглен и ултравиолетови (UV) светлинни системи. Тези технологии се използват за отстраняване на физични, химични и биологични замърсители, като по този начин се гарантира чистотата и безопасността на продукта.

Системите за филтриране осигуряват съответствие със стандартите за безопасност на храните, като ефективно премахват замърсителите, включително микроорганизми, частици и химически остатъци, от суровините и продуктите. Този процес на пречистване помага за спазване на регулаторните изисквания и поддържа високи стандарти за качество на крайните хранителни продукти.

Филтрационните системи поддържат качеството и консистентността на продукта, като премахват нежелани частици, микроорганизми и други замърсители от съставките и крайните продукти. Това гарантира, че всяка партида отговаря на желаните стандарти за чистота и качество, което води до еднаквост във вкуса, външния вид и безопасността на всички продукти.